Spot Welding

Questions and Answers

When a machine has been running good parts and a brief stop is made one expects to start back up and make good parts. The stop could be for a break, electrode change, electrode dressing, lunch or shift change. These occur every day and should not create a problem. If something is occurring what is the variable?

Some have said that the electrode cools off during the break. Possibly but it cools to merely water tower temperature of 85 deg F or if refrigerated 65 deg F. Considering that the electrode will reach red hot on the face which is 1400 deg F in less than a second. A little cooling does not matter.

One must look elsewhere. It is troubleshooting time. Something else in the system has changed and needs to be investigated. It is time to get out the current meters and force gauges. It is highly likely that in the force or voltage current world something is not being delivered as desired. Every shop should have or access to a current meter and a force gauge.

Spot welding is a form of resistance welding. The heat is generated by two opposing electrodes passing current through two or more sheets of material. The resistance to that heat flow in the materials causes them to heat up and form a weld nugget. Which when solidified bonds the two sheet together. This heating process is governed by:

The heat is generated by the current squared times the resistance in the materials by the time it is heated.

Water flow measurement is critical to ensure the components of the resistance welder and especially the electrodes are receiving the proper amount of cooling water during operation.

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines offers information about the setup and maintenance of resistance welders.

Glidcop is a tradename for a dispersion strengthened copper material classified by the RWMA. The most common form is RWMA Class 20. It is frequently used to resistance weld galvanized steel. There are other uses but this is a common usage and will be assumed the subject matter for this inquiry.

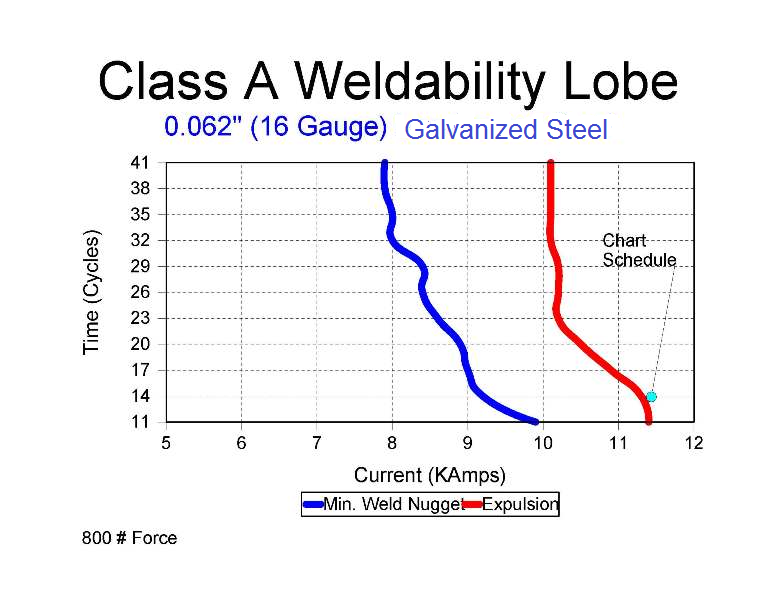

RWMA Class 20 is used in a manner similar to RWMA Class 1 and Class 2. It is most often used at or near expulsion levels of the weld lobe. It’s claims to fame are resistance to heat and anti-sticking. At various intervals during it use it is changed and dressed and reused. The other more common method in automation, the robot moves the electrodes periodically to a dressing station while the next part is loaded.

The question asked is: what is the life expectancy of RWMA Class 20? The answer depends upon what is being welded, how close is the weld schedule is to the high end of the weld lobe, how much expulsion is being experienced, how much material is being dress away?

To start this off “RO” stands for Reverse Osmosis. This is a filtration process that uses a semi permeable membrane to filter out larger particles in the water. It removes most minerals. “DM” stands for Demineralized Water. It is also called Deionized water. It also removes the minerals from the water. As the name implies the ions are removed. The pro for both is they produce pure water.

AWS has a standard for water used in resistance welding equipment:

AWS Standard J1.2M/J1.2:2016 Guide to the Installation and Maintenance of Resistance Welding Machines

Page 20 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.