Spot Welding

Questions and Answers

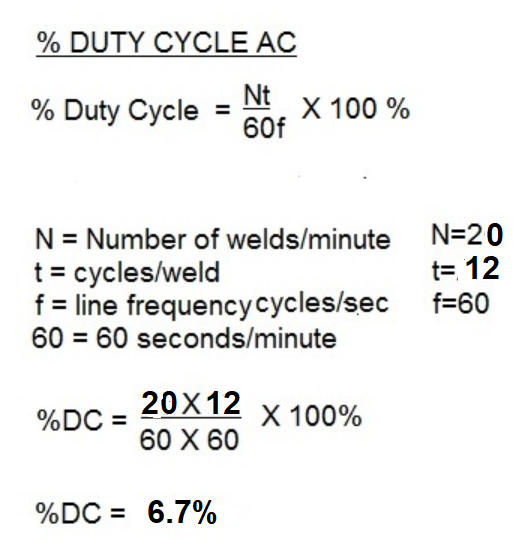

This question is asked often “How much power does my resistance welder use?” To answer this, we first need to calculate the Duty Cycle of the process. The formula for this is:

Proper alignment of the resistance welding electrodes is very important to insure proper force application and current flow through the electrode face. If not set up properly the part can be distorted and/or the electrode face can have exceedingly high current densities. This can result in distorted parts, expulsion and excessive electrode face wear.

This is the description of a typical cosmetic weld where one surface must be preserved as is. All heat and distortion must come from the other side, we will call it the back side. To do this a large “FLAT” faced RWMA “C” electrode is used on the good side. On the back side an RWMA “A” or pointed nose or in this specific case one with a face of 1.5 mm (0.060”).

The weld schedule should be designed to generate the heat from the back side and stop as the weld nugget just begins to grow into the top sheet. This will not be the best weld that could be produced. It will be a tack weld just good enough to hold the part together until the braze is made.

If discoloration is an issue water misting cooling, a gas shield or any other means could be used to prevent heat or oxidation on the one side.

COSMETIC WELD NUGGET MOSTLY IN ONE COMPONENT

Reference: RWMA - Resistance Welding Manual 4th Edition

The answer to this is there is none. One can measure a weld nugget after it is made. One cannot calculate a weld nugget in advance, since one has not preset any of the variables of the process. The simple variables are squeeze, weld and hold. They quickly expand into force/pressure, electrode material, electrode wear and face size, coating pick up on electrode face, material being welded, surface condition, coating and on and on. There are many more but we will stop here. All of these variables will influence changes in the weld schedule that will directly change the size of the weld nugget.

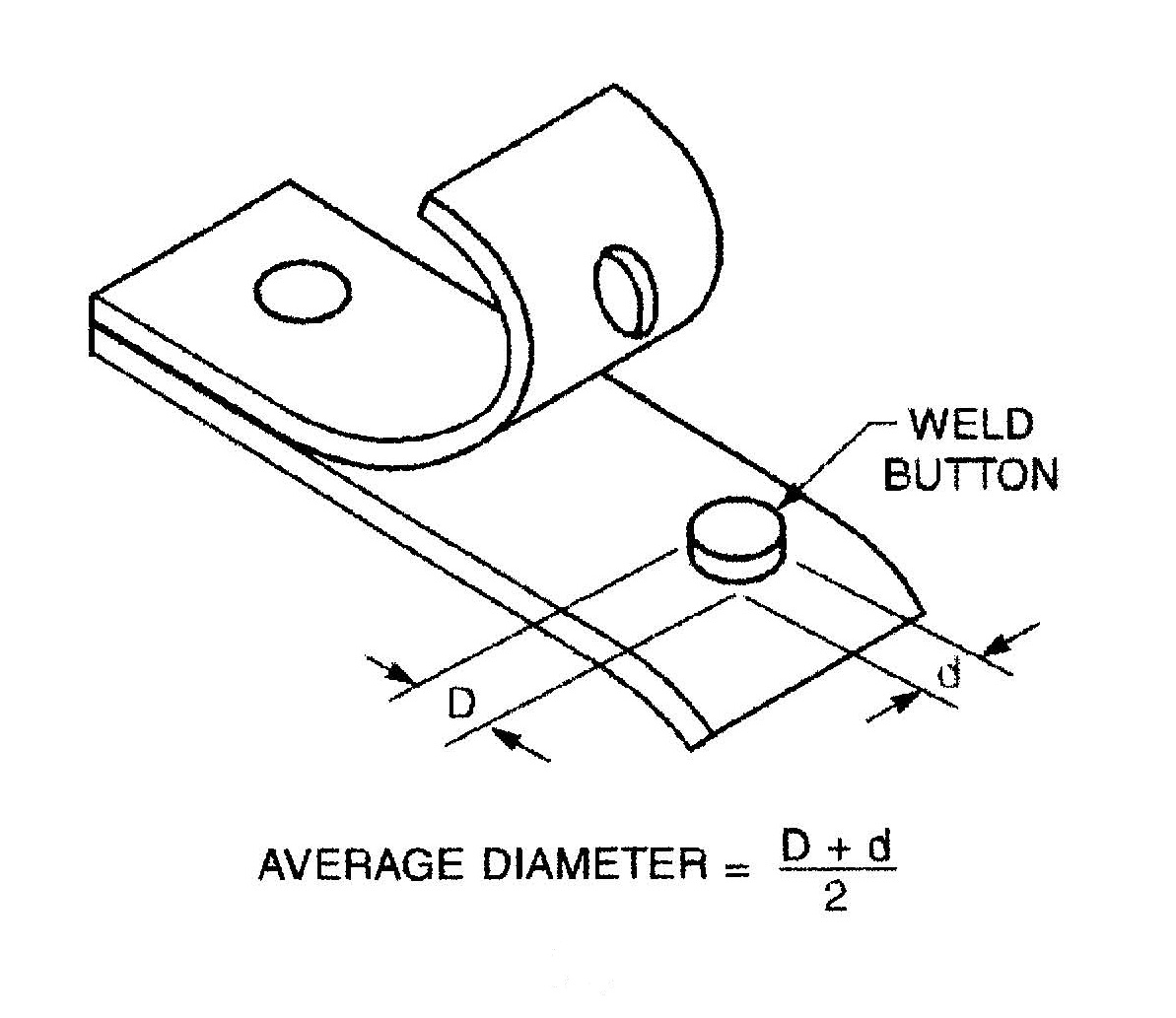

The resultant pulled weld nugget is measured with a set of calipers in two directions, 90 degrees apart.

This is how to measure a weld nugget.

No one has the ability to predict with calculatable accuracy what nugget size a given set up will produce.

Welding guns use special copper alloy arms/adapters which function as electrode holders. They attach to the gun on one end and have a cap taper at the other for the electrode. They are frequently called cap adapters.

CAP ADAPTERS

With time these adapters wear out. A common failure mode is the electrode taper.

The question is can cap adapters be repaired?

A faulty bend or cracked adapter is not repairable.

Tapers are being repaired. This is done on a limited basis depending upon the application, design and condition of the adapter. Keep in mind a repaired adapter is not as strong will not have the life of a new adapter. Repaired adapter could be held in reserve for when new adapters are not available.

A new adapter is the better choice for production line continuity.

Reference: Photo courtesy of -Tuffaloy Resistance Welding Products Catalog

Page 15 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.