Spot Welding

Questions and Answers

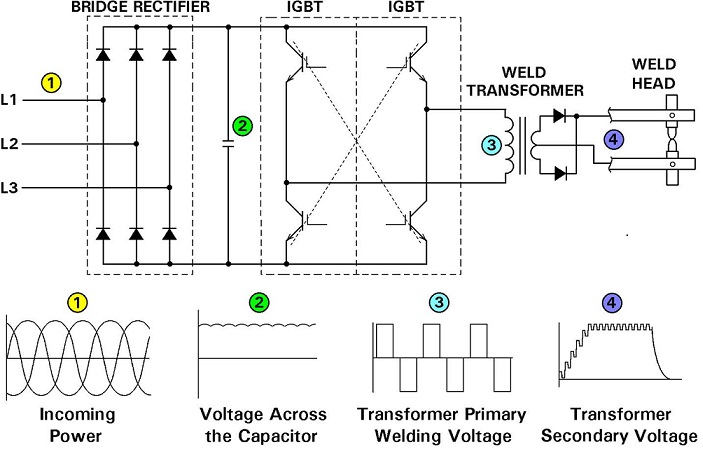

The basic conversion process of AC to DC or MFDC is discussed in an article in this blog:

HOW IS AC CONVERTED TO DC WITH A FREQUENCY OF 600Hz?

CONVERSION IN CONTROL AND TRANSFORMER of MID FREQUENCY INVERTER

The components and their functions are discussed in the article referred to above. A similar product will be necessary for any high frequency conversion.

The actual design is beyond the scope of this blog.

Reference: RWMA Manual, Fourth Edition

You mentioned that additional cooling apparently has helped a few spots reduce distortion of your thin parts and mesh. Some of your product is seam welded.

Cooling of the electrodes themselves is the most important step. They need lots of water and as cool as possible. An article on this topic is:

HOW COLD SHOULD THE WATER BE FOR RESISTANCE WELDING?

Additionally, the water in the electrode needs to be near the electrode face. In some applications the backup electrode is a large surface or block. This should be a copper conductor and have water passages bored in it for good water cooling.

NOTE THE BORED WATER-COOLING HOLES ON THE SIDE

OF THE TRANSFORMER FACE PLATE

This can be one through hole or a series of connected holes depending upon the heat being generated.

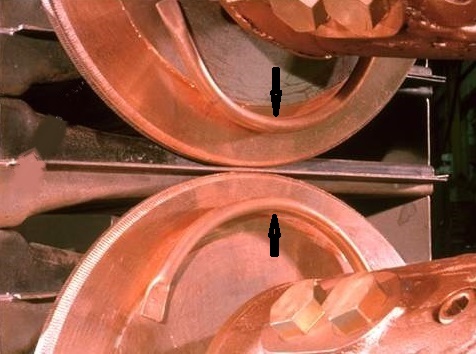

In the case of seam welding the water cooling is not near the weld area. An option used frequently for seam welding is flood cooling. Water is sprayed directly on the part at the weld site during the weld. This helps cool both the weld wheel and the part.

ARROW SHOWS WATER SPRAY COOLING TUBE

To reduce distortion, the part can be held in place by insulated blocks that prevent the distortion as desired until cooling has finished. This is all part of the tool design

Reference: RWMA - Resistance Welding Manual 4th Edition

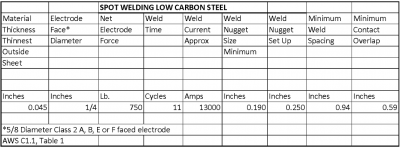

The final acceptance criteria for quality may be determined by agreement between the manufacturer and the user. Prior to that accepted industrial standards are frequently referenced for possible use in the various applications. One location for these standards is the American Welding Society. AWS publishes technical standards. Many applications with helpful start up data can be found in:

AWS Standard C1.1- Recommended Practices for Resistance Welding

This standard will include tables with data that is applicable to many applications in industry.

This is an excerpt from a much larger table. There are many tables on many steels and nonferrous materials. Each table offers the same and more information on set up and testing including weld nuggets, shear strength and other weld schedule related data. The processes included are Spot, Projection, Seam , Butt and Flash welding.

Reference: AWS Standard C1.1 Recommended Practices for Resistance Welding

Several articles in this blog discuss Projection Welding. Including:

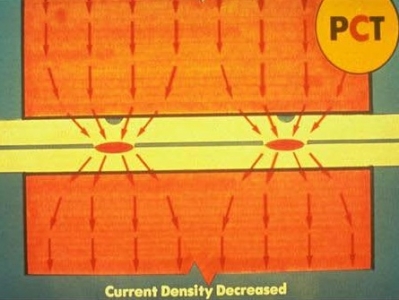

The important item to draw from this discussion is that the projection concentrates the heat and energy into a spot. The electrode is merely used to introduce that power into the part, which by design concentrates the power into a localized spot and concentrated heat is generated there.

ELECTRODE CURRENT DENSITY LOWERED

The choice of the electrode material and design is relatively simple.

Choose an economical electrode material to cover more than the area of the projection. This will reduce localized heating and wear of the electrode. In simple terms a large flat surface works for a flat part. A little surface wear will occur with time. Refacing may be needed for cosmetics at some point but not nearly as frequent as in spot welding.

The electrode material should be selected based on the materials being welded not the coatings.

Charts are available to select electrode material based on materials being welded in the references listed.

Reference: Tuffaloy Resistance Welding Products Catalog – Recommended Electrode Materials Chart.

AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition

Aluminum has a very high expansion and contraction during heat cycles. This in combination with a narrow plastic range make the weld nugget subject to crack formation during solidification. The fast contraction can lead to weld failure as welded.

Normally resistance welds are made with fast heat up. With two water cooled electrodes on the surface of the aluminum it will cool down fast. This is where the problem begins. There is a shrinkage in volume as it shrinks so the electrode system must have good fast follow up in order to maintain constant force.

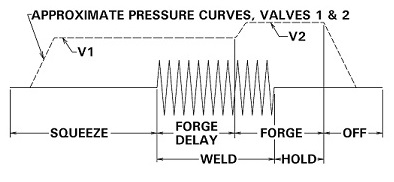

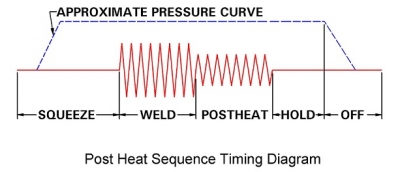

Another tool sometimes used is a slowed cool down along with carefully timed forging to reduce the shrinkage voids.

If the voids are reduced or eliminated the aluminum weld will have greatly improved integrity.

American Welding Society - AWS Standard Publication C1.1 Goes into depth on the methods and has weld schedules for a few sample aluminum materials to explain the processes used.

As stated in the AWS C1.1 the timing of the post heat and forging action is critical in order to close the voids before the aluminum has solidified but not too soon or one could dissipate the heating effect of the forging current.

See:

CAN ALUMINUM WELDS BE IMPROVED WITH FORGING?

Reference: RWMA Resistance Welding Manual 4th Edition

AWS Std C1.1 Recommended Practices for Resistance Welding

Page 1 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.