Several articles in this blog discuss Projection Welding. Including:

The important item to draw from this discussion is that the projection concentrates the heat and energy into a spot. The electrode is merely used to introduce that power into the part, which by design concentrates the power into a localized spot and concentrated heat is generated there.

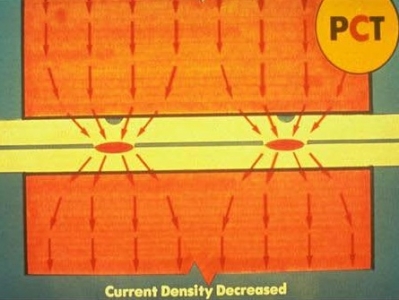

ELECTRODE CURRENT DENSITY LOWERED

The choice of the electrode material and design is relatively simple.

Choose an economical electrode material to cover more than the area of the projection. This will reduce localized heating and wear of the electrode. In simple terms a large flat surface works for a flat part. A little surface wear will occur with time. Refacing may be needed for cosmetics at some point but not nearly as frequent as in spot welding.

The electrode material should be selected based on the materials being welded not the coatings.

Charts are available to select electrode material based on materials being welded in the references listed.

Reference: Tuffaloy Resistance Welding Products Catalog – Recommended Electrode Materials Chart.

AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition