Butt Welding

Questions and Answers

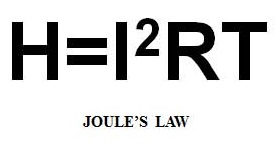

Butt welding is a very similar process to flash welding. One relies upon Joules Law for heat Butt Welding (Upset Welding).

Flash Welding relies upon the energy of an electrical arc to generate the heat.

The movement, upset and equipment are similar for the two processes.

Parameters for flash welding are published in:

AWS C1.1 – Recommended Practices for Resistance Welding

AWS C1.1 document states for upset welding the same welding parameters except those related to flash, can be used as a guide to develop upset welding schedules.

This is the source for start-up data. The data available in AWS C1.1 offers welding values that will make welds.

As in all resistance welding processes a starting point based on available data is chosen a little on the cold side. Then adjusted until the desired results are obtained.

References: AWS C1.1 - Recommended Practices for Resistance Welding

RWMA – Resistance Welding Manual 4th Edition

Butt Welding and flash welding are similar processes in that they both clamp the part and force it together to form a bond. The difference being one arc welding initiates the current before bringing the two faces together and an arc is formed generating massive heating. The other brings the parts together and then initiates the power and uses:

to generate the heat - butt welding. The processes in terms of clamping, time, part movement and clamping are similar.

Typical applications: wheel rims are often flash welded and wire is frequently butt welded in wire mills.

BUTT WELD

There is not a great deal of data published on these processes.

The American Welding Society Standard C1.1 “Recommended Practices for Resistance Welding” has a modest amount of data on flash welding. This data can be used for butt welding since they are similar processes.

Another article in this blog describes trouble shooting a butt weld application:

WE NEED HELP BUTT WELDING 0.500" , 1008 STEEL ON A 30 KVA WELDER.

Besides these sources the only other option might be flash or butt welder manufacturers who would have experience and may be able to lend some knowledge to your application.

References: RWMA – RWMA Resistance Welding Manual 4th Edition

AWS- AWS Standard C1.1 Recommended Practices for Resistance Welding

The answer is yes, but? Pipe ends can be butt welded together to make longer lengths. Steel rods are butt welded frequently to increase length. In the case of pipe there will be flash or upset on the inside diameter. This must be tolerated or removed by some inventive means. The ends could be formed into a loop and welded. There will be flash on the interior which would be very difficult to remove.

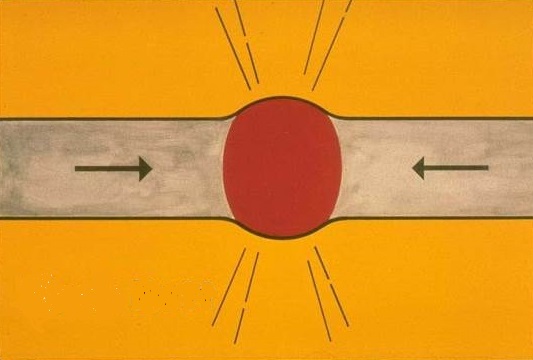

Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. After the parts are clamped and brought together with force a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow.

As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete. This differs from flash welding, where the current is applied before the two pieces come together. This creates the flash.

A very similar inquiry came in previously. That person was butt welding 0.500” diameter 1008 steel on a 30 KVA machine. The machine apparently was adequate. The issue was fine tuning the welding parameters. Your 4140 steel is stronger but could probably work on a similarly sized machine.

Page 1 of 4

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.