The answer is yes, but? Pipe ends can be butt welded together to make longer lengths. Steel rods are butt welded frequently to increase length. In the case of pipe there will be flash or upset on the inside diameter. This must be tolerated or removed by some inventive means. The ends could be formed into a loop and welded. There will be flash on the interior which would be very difficult to remove.

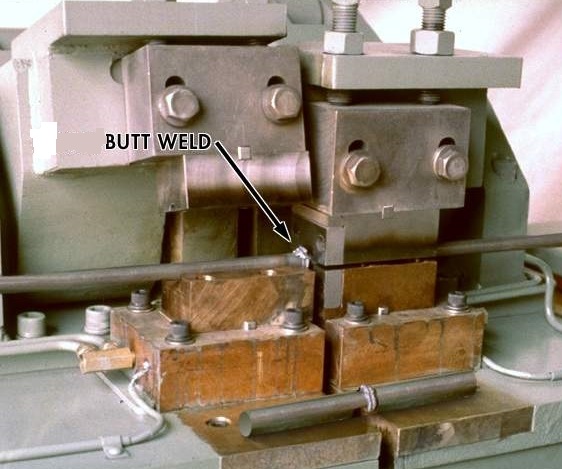

BUTT WELDED STEEL ROD

If the pipe is a large size a flash weld may be a better choice. Again internal upset/flash will be present and have to be addressed.

A typical process for large wheel rims is:

• Steel is formed into rings• Flash welded

• Flash is removed

• The flash welded preform is frequently rolled into BIG RIG TRUCK WHEELS for highway, off road and farm use.

Pipe could also be flash welded similarly. Flash removal on the Internal diameter if needed would have to be addressed.

Reference: RWMA – Resistance Welding Manual 4th Edition