Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. The parts are clamped and brought together with force and a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow. As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete.

A frequently used process for butt welding is welding metal rod ends together in a metal rod or wire mill. As each butt weld is made the resultant flash or upset material is mechanically removed for ease of drawing through the draw die. Multiple rod ends are welded end to end and then drawn through a draw die to size the rod to a slightly smaller size. It is frequently coiled on a coiler as it is drawn. When the desired numbers of rods have been welded together, the resultant coil is then drawn through a series of smaller dies until it is at the desired finish size. This is how rod is turned into a coil of wire. The welds are fast reliable and repeatable. The butt welds are virtually indiscernible.

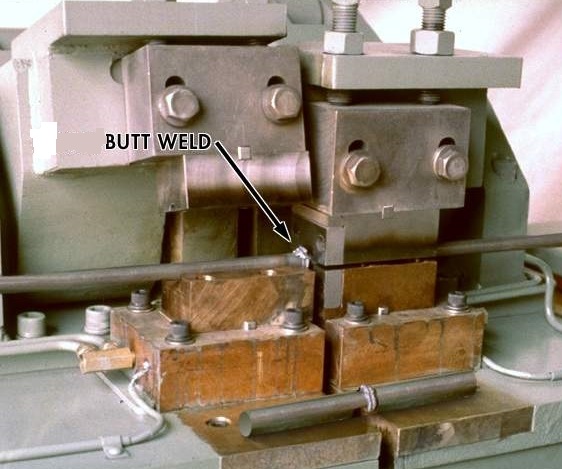

Rod Butt Welder

Reference: RWMA – Resistance Welding Manual Section 5