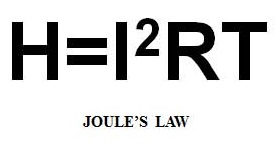

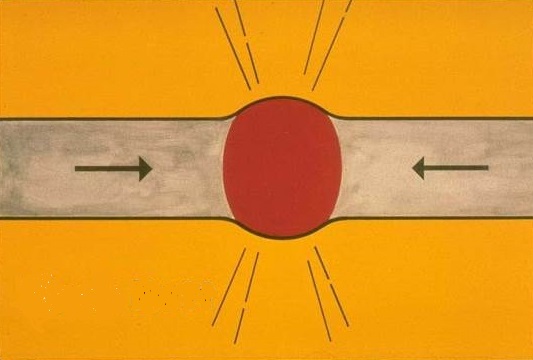

Butt Welding and flash welding are similar processes in that they both clamp the part and force it together to form a bond. The difference being one arc welding initiates the current before bringing the two faces together and an arc is formed generating massive heating. The other brings the parts together and then initiates the power and uses:

to generate the heat - butt welding. The processes in terms of clamping, time, part movement and clamping are similar.

Typical applications: wheel rims are often flash welded and wire is frequently butt welded in wire mills.

BUTT WELD

There is not a great deal of data published on these processes.

The American Welding Society Standard C1.1 “Recommended Practices for Resistance Welding” has a modest amount of data on flash welding. This data can be used for butt welding since they are similar processes.

Another article in this blog describes trouble shooting a butt weld application:

WE NEED HELP BUTT WELDING 0.500" , 1008 STEEL ON A 30 KVA WELDER.

Besides these sources the only other option might be flash or butt welder manufacturers who would have experience and may be able to lend some knowledge to your application.

References: RWMA – RWMA Resistance Welding Manual 4th Edition

AWS- AWS Standard C1.1 Recommended Practices for Resistance Welding