You mentioned that additional cooling apparently has helped a few spots reduce distortion of your thin parts and mesh. Some of your product is seam welded.

Cooling of the electrodes themselves is the most important step. They need lots of water and as cool as possible. An article on this topic is:

HOW COLD SHOULD THE WATER BE FOR RESISTANCE WELDING?

Additionally, the water in the electrode needs to be near the electrode face. In some applications the backup electrode is a large surface or block. This should be a copper conductor and have water passages bored in it for good water cooling.

NOTE THE BORED WATER-COOLING HOLES ON THE SIDE

OF THE TRANSFORMER FACE PLATE

This can be one through hole or a series of connected holes depending upon the heat being generated.

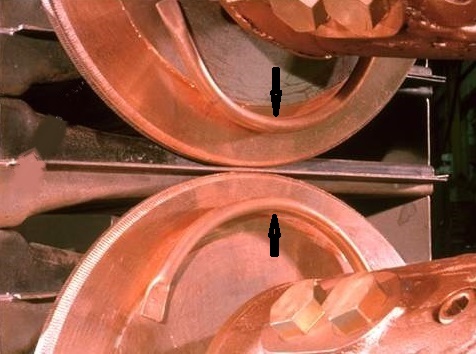

In the case of seam welding the water cooling is not near the weld area. An option used frequently for seam welding is flood cooling. Water is sprayed directly on the part at the weld site during the weld. This helps cool both the weld wheel and the part.

ARROW SHOWS WATER SPRAY COOLING TUBE

To reduce distortion, the part can be held in place by insulated blocks that prevent the distortion as desired until cooling has finished. This is all part of the tool design

Reference: RWMA - Resistance Welding Manual 4th Edition