Spot Welding

Questions and Answers

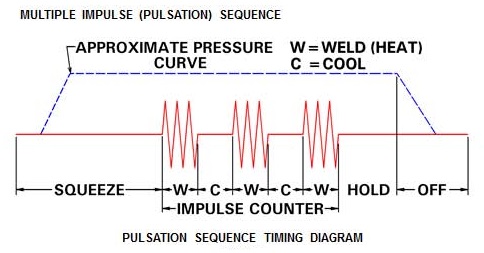

Generally, when spot welding with the same electrode on both sides of the weld, the resulting weld nugget is smaller than the electrode face diameter. To obtain a nugget larger than the electrode face diameter extra growth time and or heat is applied to accommodate additional growth. Pulsing is a common method used to do this.

Without some extra time or heat it is not common to see nuggets larger than the electrode face. That is not to say it is not impossible. If one works out a schedule that has the heat over a long enough period with sufficient heat to grow the nugget without creating expulsion – IT CAN BE DONE!

This question has already been answered by another article in this blog.

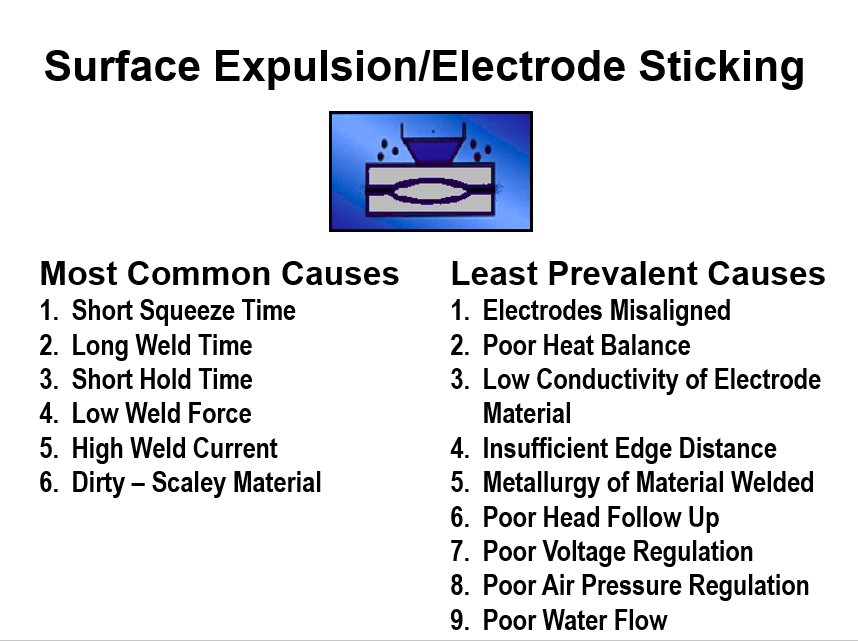

"WHY DO I HAVE SURFACE EXPULSION?"

The only additional comment is that the galvanized zinc coating melts at a low temperature and is very prone to expulsion and could contribute to the popping sounds. This could be item 5 under least prevalent causes. Otherwise below is:

"WHY DO I HAVE SURFACE EXPULSION?"

Surface expulsion is caused when the part surface heats up. So anything which would cause this, could be a reason. The appearance is similar to interface expulsion. In this case we are looking for conditions which cause the contact surface heat to be high.

This question is a sales marketing question which is beyond the scope of this blog.

I can suggest contacting your local resistance welding supplier or the:

RESISTANCE WELDING MANUFACTURERS ALLIANCE “RWMA”

OR

AMERICAN WELDING SOCIETY “AWS”

FULL SIZE ELECTRODE AND MALE CAP

This question is not clear to the author of this blog. Resistance welding materials are classified by their material compositions and properties. In North America the Resistance Welding Manufacturers Alliance (RWMA) and American Welding Society (AWS) publish this data.

RWMA Resistance Welding Manual 4th Edition

AWS Standard J1.3 Specification for Materials Used in Resistance Welding Electrodes and Tooling

This blog has various articles describing the various material Classes of resistance welding electrode materials specified by the RWMA.

FULL SIZE ELECTRODE AND MALE CAP

Specifications of common designs, specifications, application and common uses are also described in the referenced documents and articles. Similar documents are published by ISO and Asian standards organizations.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS Standard J1.3 Specification for Materials Used in Resistance Welding Electrodes and Tooling

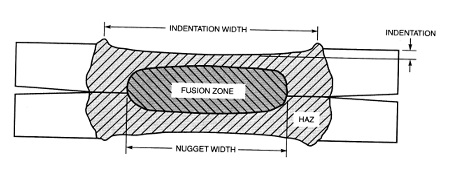

Indentation is defined as the depression made by the electrode into the outer surface of the part being resistance welded.

The figure above defines indentation. The product being welded in many cases may define the amount of indentation allowed. A show surface like the hood of an automobile would be a no-show surface therefor no indentation is acceptable on the face side. This is commonly refered to as a cosmetic weld (one side has little of no indentation). On a weld surface inside the trunk or under the hood, indentation may be acceptable at some level.

Page 16 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.