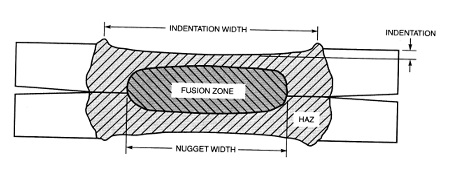

Indentation is defined as the depression made by the electrode into the outer surface of the part being resistance welded.

The figure above defines indentation. The product being welded in many cases may define the amount of indentation allowed. A show surface like the hood of an automobile would be a no-show surface therefor no indentation is acceptable on the face side. This is commonly refered to as a cosmetic weld (one side has little of no indentation). On a weld surface inside the trunk or under the hood, indentation may be acceptable at some level.

The level of acceptability is determined by the product, industry, design, location, manufacturer and customer. The drawing above defines indentation. The amount permitted will be determined as already described by the product, industry, design, location, manufacturer and customer. It is common for the drawing shown above to permit an acceptability up to 30% indentation into the surface thickness, if indentation is permitted. This is a value that must be evaluated and developed per part, location and application. There is no one size fits all.

Reference: RWMA: Resistance Welding Manual 4th Edition

AWS Standard D8.2 :2017 Specification for Automotive Weld Quality – Resistance Spot Welding of Aluminum