Spot Welding

Questions and Answers

A resistance welding schedule has three defined segments. They are:

SQUEEZE

WELD

HOLD

This question comes up frequently. Many look for a formula to set the squeeze and hold time for resistance welding.

Several articles have been written on this subject in this blog:

HOW DO YOU SET THE PROPERSQUEEZE TIME IN A RESISTANCE WEDING SCHEDULE?

IS THERE A FORMULA TO DETERMINE THE SQUEEZE TIME IN RESISTANCE WELDING?

IS SQUEEZE TIME IMPORTANT?

HOW WILL HOLD TIME CHANGE THE RESISTANCE WELD STRENGTH?

Pressure, current and time (PCT) are the basic functions performed by the resistance welder. These functions are controlled or initiated by the weld controller. It initiates each step when told to start the weld process by input from the foot switch or automation PLC. The controller allows time for each step to operate and controls the current amplitude. In simplified form this is Squeeze, Weld and Hold. The squeeze sequence allows the pressure system to build up the force to contain the weld. The weld function is the actual current flow and is totally controlled by the weld controller. It regulates the amplitude and time of current flow. Hold is the period which allows the weld nugget to cool down and solidify under force. The controller regulates this time.

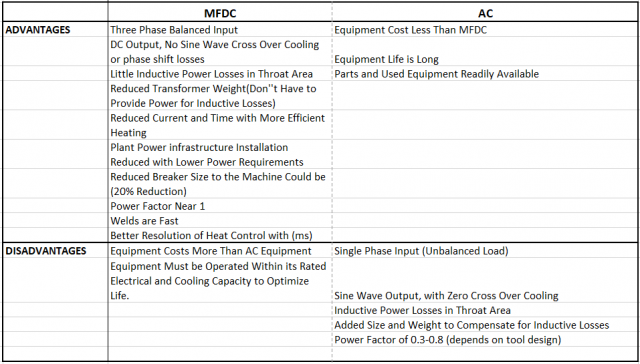

Why do so many projection welds continue to be made on AC machines when MFDC has so many advantages?

MFDC systems over the last twenty years have been the dominant new welding system. It has found usage in most new installations. That is not to say that AC systems do not have their place in the industry. They do and will continue to be used. Below is a comparison of the two systems pro & con:

An inquiry came in suggesting that two forces are responsible for creating a resistance weld. Let’s examine this question. To do so we will look at two previously published articles in this blog:

“WHAT IS AC RESISTANCE WELDING”

AND

“WHAT IS THE DEFINITION OF RESISTANCE WELDING”

Per the definition of the Resistance Welding Manufacturers Alliance:

RESISTANCE WELDING IS THE JOINING OF METALS BY APPLYING

PRESSURE

AND PASSING

CURRENT

FOR A LENGTH OF

TIME

THROUGH THE METAL AREA WHICH IS TO BE JOINED

Page 19 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.