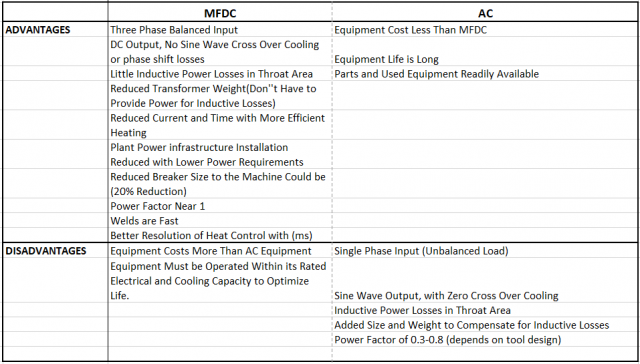

MFDC systems over the last twenty years have been the dominant new welding system. It has found usage in most new installations. That is not to say that AC systems do not have their place in the industry. They do and will continue to be used. Below is a comparison of the two systems pro & con:

COMPARISON OF MFDC VS AC

A more complete comparison can be found in another article in this blog:

COMPARE MFDC vs AC IN RESISTANCE WELDING

If we look at projection welding. Projection welding has worked well with AC for years.

MFDC works best when:

• There is a power shortage

• Need short weld time

• There is a need to restrict the heat effected zone

• There is a requirement to reduce the weight or size of the weld equipment

AC works best when:

• The MFDC need parameters listed above are not necessary

• AC equipment is available to repurpose to a new application.

• Personnel are familiar with the AC equipment. No training necessary.

• Equipment has long life

Repurposing or bringing in a new piece of equipment similar to the previous and its long life is where AC performs best.

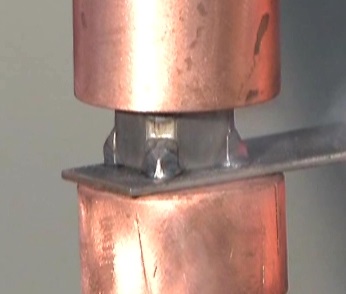

MFDC RING PROJECTION AC PROJECTION WELD

WELD @ 30 Ka for 100 ms

MFDC Inroads:

MFDC has made improvement with applications that push the envelope for AC.

Examples are Larger spud welding with high power needs and nut welding where short weld time has resulted in better weld quality. In the large spud welders, MFDC delivers large amounts of power from a balanced three-phase input with very short weld times. In nut welding some of high strength steels weld best with short 10 – 30 millisecond weld times. This requires MFDC. These short weld times reduce the embrittlement of the weld.

To summarize, the marketplace that uses robots use MFDC systems to reduce weight. Some use MFDC for technical reasons (short heat times).

AC Facilities:

Those facilities not using robots have a choice and often they repurpose used AC systems or stick with familiar AC systems that cost less, unless there is a technical/power reason to upgrade to MFDC.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS – Welding Journal, Q & A July 2019