Spot Welding

Questions and Answers

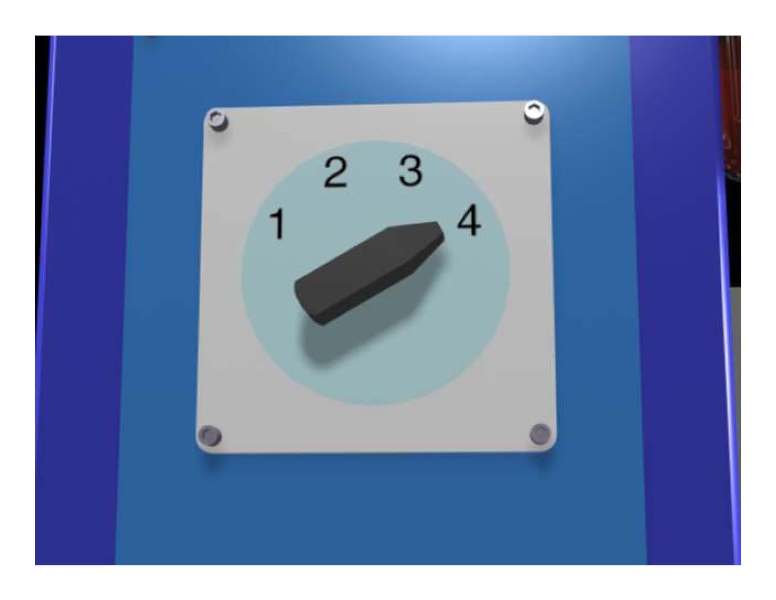

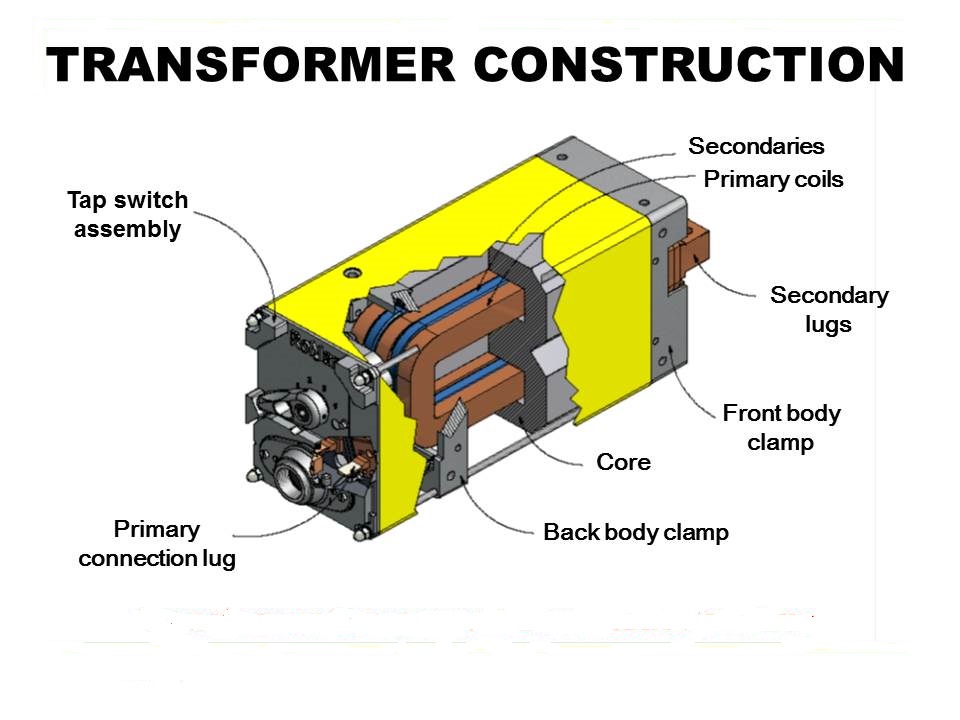

Yes, changing the transformer turns ratio will change the current. A transformer with a tap switch works on this principal. The tap switch is wired to various points in the primary winding in order to vary the turns ratio. By changing the tap switch position the turns ratio is changed. One can choose the lowest voltage and resultant current in Tap 1 or the highest voltage and current output in the highest Tap. The number of taps and their range depend upon the transformer design.

Press Welder Transformer Tap Switch

Many weld transformers are manufactured with a tap switch. This tap switch gives one the ability to change the turns ratio as needed. The net result is the output voltage changes up or down as the tap is changed.

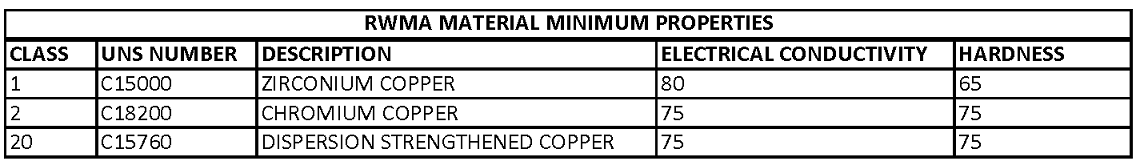

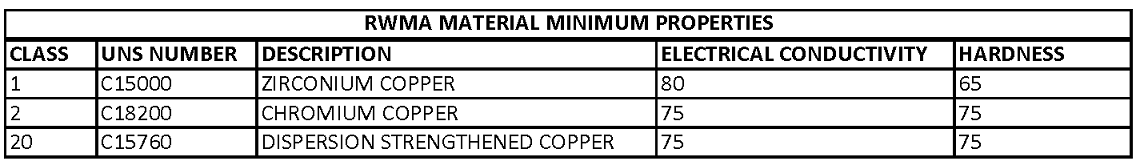

A common use for RWMA Class 20 material is spot welding of galvanized steel. Its properties of anti-sticking and heat resistance have made it one of the choices for this sometimes difficult welding operation. Other materials Class 2 and Class 1 can and are used for galvanized also. What makes this premium material a choice to consider for galvanized steel welding?

It is well known that the zinc/galvanized coating readily alloys with the copper of the electrode and weakens its surface structure and forms a layer of brass on the welding surface. Any electrode alloy which maintains its strength and retards this surface condition is a candidate for galvanized welding.

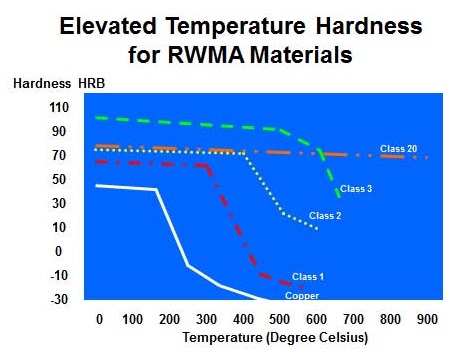

In this chart Class 20 is shown to resist heat and maintain it strength at elevated temperatures. In resistance welding to take advantage of these properties Class 20 should be used in higher heat applications. In many cases it is used exactly this way. The weld schedules are being run hot. The electrodes are subjected to a lot of heat, potential annealing, mushrooming, brassing and sticking. The weld schedule by choice is being run at the high end of the weld lobe.

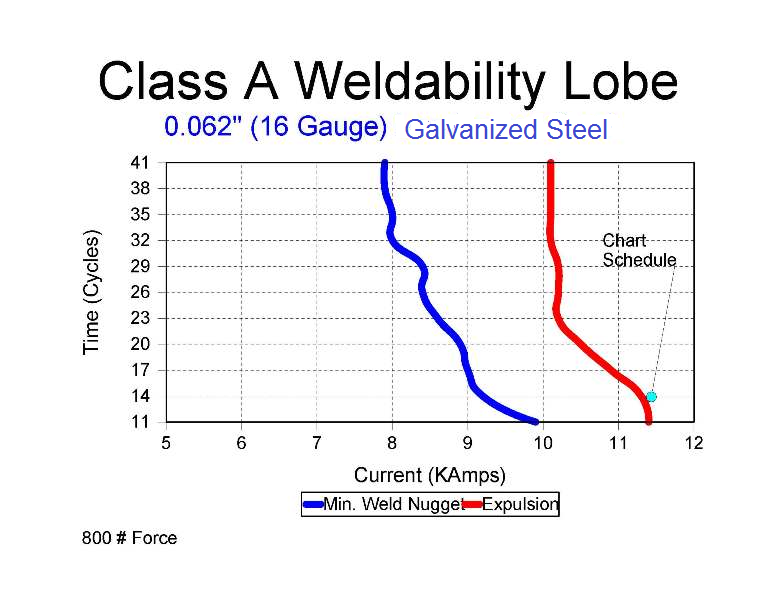

In the weld lobe shown a good weld can be made at 14 cycles with 9.5-11.5 amperes. Class 20 applications are used when the schedule is set to run at 11.5 as marked. This means the electrode will see expulsion frequently if not all of the time. These companies want to insure they are hot enough to never be cold and fall to the left of the blue line. They choose to use a premium electrode material and run hot to insure nugget integrity. With wear the nugget will still fail but with history they know when and change electrodes or redress before this happens.

The other choice of course is to turn the current down below the expulsion level and operate between the blue and red line with a safety factor.

Other materials with similar properties are:

The other choices are either RWMA Class 2 or Class 1 alloy electrode material depending upon how hot you are running. At the reduced heat operating levels between the red and blue lines these alloys will perform well. Most of industry is welding galvanized and coated materials with RWMA Class 1 and 2.

If you are considering changing electrode material and potentially altering the weld schedule, keep in mind the following:

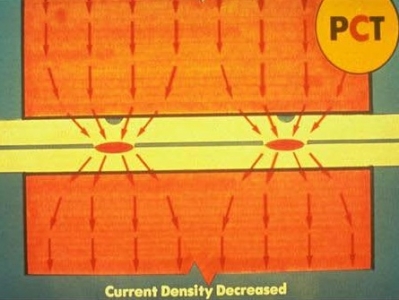

Pressure, current and time (PCT) are the variables that could be adjusted. This may lead to requalification of the weld set-up depending upon your in house procedures and the amount of the schedule change.

Reference: RWMA Resistance Welding Manual 4th Edition

AWS J1.3 Specifications for Materials Used in Resistance Welding electrodes and Tooling

A common use for RWMA Class 20 material is spot welding of galvanized steel. Its properties of anti-sticking and heat resistance have made it one of the choices for this sometimes difficult welding operation. These good properties do come at a premium over other materials with similar properties.

The problem encountered when welding galvanized is that the zinc/galvanized coating readily alloys with the copper of the electrode and weakens its surface structure and forms a layer of brass on the welding surface. Any alloy which maintains its strength and retards this surface condition is a candidate for galvanized welding. Class 20 dispersion strengthened copper is a good candidate but not the only one.

RWMA Class 2 chromium copper is another alloy often used to spot weld galvanized. Its hardness and electrical conductivity are virtually the same as Class 20. With these properties it can function in the same welding environment and perform the same functions without a material premium charge.

RWMA Class 1 zirconium copper also has great electrical conductivity and good hardness and finds good success spot welding galvanized materials without a material premium.

Both Class 1& 2 can be substituted for Class 20 for welding galvanized material. In fact, Class 1 & 2 are the biggest users in the galvanized resistance welding marketplace and are stocked in most rod, bar and electrode sizes.

Substituting one electrode alloy for another may require adjustments to the weld schedule. Pressure, current and time (PCT) are the variables that could be adjusted. This may lead to requalification of the weld set-up depending upon your in house procedures and the amount of the schedule change.

Reference: RWMA Resistance Welding Manual 4th Edition

AWS J1.3 Specifications for Materials Used in Resistance Welding electrodes and Tooling

Generally projection welding electrodes are large flat surfaces. Sometimes holes are incorporated for locators (nut welding). In crosswire welding the lower electrode may be a single long bar of copper alloy or refractory material spanning many welds. The electrode delivers force and amperage through a relatively large surface area into the part being welded. Secondarily they provide cooling of the part.

The part by design concentrates the current and force to create heat and forging at a concentrated location. Projection welding electrode life is long when compared to spot welding electrodes. The wear is frequently mechanical abrasion. RWMA Class 2 is the first choice for electrode material in projection welding. If mechanical wear and tear is a little heavy and Class 2 has to be faced too often, try RWMA Class 3. It is mechanically harder and more resistive to wear than Class 2. If there is a lot of heat and excessive wear turn to RWMA Class 11, refractory metal electrodes may be the best choice. Nut welding sometimes is a heat generator and the Class 11 refractory electrodes are successfully used. Electrically Insulated locator pins are employed when needed.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

AWS J1.3 Specification for Materials Used In Resistance Welding Electrodes and Tooling

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

It will be assumed that a 1000 volt primary supply is connected to the primary of a resistance welding transformer. The question is should this produce amperage on the secondary? Assuming that the control is functioning, wiring is correct and the transformer is good the answer is yes. There should be voltage and current at the transformer secondary terminals. The amount depends upon the equipment.

This means that many items need to be verified to insure that all is correct. If all is correct and there is no voltage and current present at the secondary, back up the circuit and test.

Is there voltage at the primary?

Is the transformer grounded properly? If the transformer is failing to ground it should have tripped a breaker. In either case investigate the transformer.

Is there a properly sized breaker on the system?

If the transformer is good, move up a level.

Then back up another lever head to the control etc. Check all connections and fuses. The control could be failing and not activating the SCR. A component has failed or is wired improperly somewhere. Search till it is found.

A conductor, fuse, component has failed somewhere in the system. A 1000 volt connection will flow if connected and the components are functioning properly.

Reference: RWMA - Resistance Welding Manual 4th Edition

AWS - J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Page 22 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.