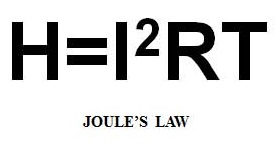

Spot welding is a form of resistance welding. The heat is generated by two opposing electrodes passing current through two or more sheets of material. The resistance to that heat flow in the materials causes them to heat up and form a weld nugget. Which when solidified bonds the two sheet together. This heating process is governed by:

The heat is generated by the current squared times the resistance in the materials by the time it is heated.

Spot welding galvanized material provides a unique challenge because the material has a zinc coating. Zinc melts at a lower temperature than the steel being spot welded. Zinc readily alloys with the copper alloy electrodes and coats their faces with brass and oxides. The welding interface changes dramatically as compared to welding bare steel. Resistance welding coated steel is more difficult but not impossible. Since the 1970’s all vehicles shifted to galvanized coated materials to reduce rust. Processes changed but galvanized parts are being spot welded successfully all over the world.

In general:

• Currents are a little higher

• Electrode faces must be dressed more frequently

• Electrodes are changed more frequently

• Stepper schedules are sometimes employed

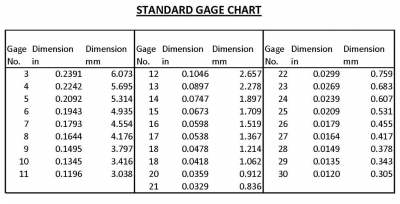

Addressing the question asked, first address what is 16 gauge:

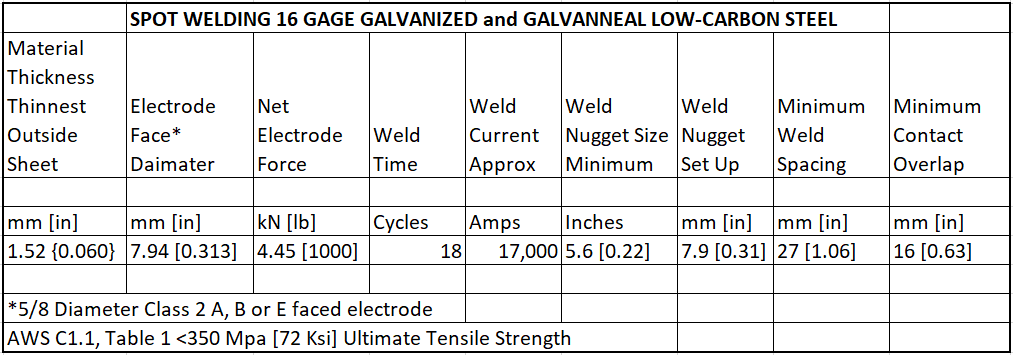

#16 gage material is 1.519 mm [0.060 in] thick. With this information one can research the various sources for galvanized weld schedules in the literature. Below is an excerpt from one:

AWS C1.1 Recommended Practices for Resistance Welding

As in all weld schedules these values will work for the material listed on a resistance welder. There is no best schedule. The machines vary, the materials vary and the specification vary therefor the actual best values will vary in every application. However, a weld nugget can be formed with the numbers listed above. With a modest amount of adjustment to fit your welding equipment, materials and specifications, parts can be run successfully.

Equipment and material suppliers are also a source of assistance for welding galvanneal coated steel. Additional weld schedules are listed in AWS C1.1. and can be obtained through AWS. RWMA Resistance Welding Manual is also a good source of information.

A related article is:

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition