Spot Welding

Questions and Answers

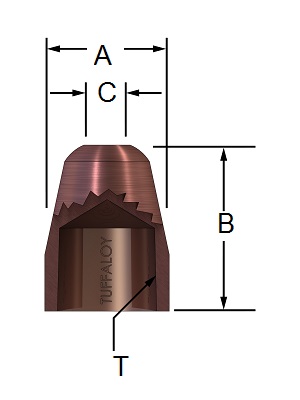

MALE CAP & FULL SIZE ELECTRODE "A" NOSE

The choice of cap vs full size standard electrode comes down to job shop, frequent set ups and length of production runs. Caps are the choice for long runs or in highly automated facilities. Full sized electrodes are the norm in job shops where short runs and frequent job changes are the norm.

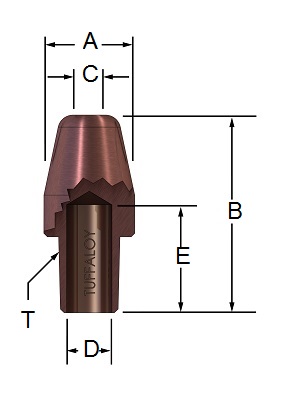

FEMALE CAP "A" Nose MALE CAP "A" Nose

Resistance welding caps both female and male are usually used in high volume and automated applications. In press welders resistance welding caps and shanks are frequently used to reduce copper electrode costs.

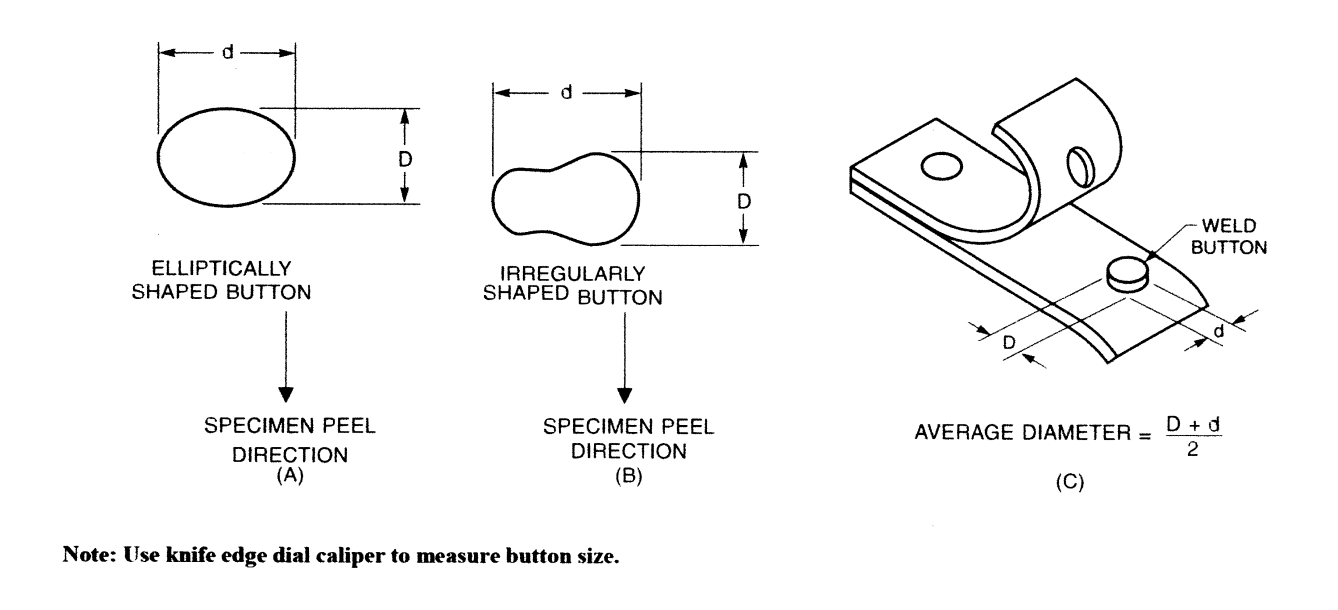

Spot welding electrodes require dressing or conditioning back to original face geometry whenever the resultant weld nugget is getting smaller and approaching an unacceptable size. This is determined through quality checks of the product or coupons as determined by your quality program. Most checks are made by destructive means. The two sheets of metal are clamped in a vise and chiseled or pulled apart. The average of the measured length and width of the resultant pulled nugget is the value being sought.

The quality system normally will specify a minimum which must be maintained. In some facilities tensile tests are specified and similar samples are pulled and tested at specified intervals to insure quality. The need for dressing the electrode and testing of product applies not only to spot welding but also projection and seam welding.

Resistance welding electrode sizes are determined by referring to published weld schedules and looking up the recommended electrode size. Resistance welding electrode size is determined by the electrode body diameter and the electrode face diameter. These are determined by the work piece being welded and the forces and currents being used to develop a proper weld nugget.

The size 4 and 5 designate the body size of the electrode. A #4 electrode has a ½” body diameter with a 3/16” face diameter. A #5 electrode has a 5/8” body diameter with a ¼” face diameter. These are sizes established by the Resistance Welding Manufacturers Alliance (RWMA) and are published in Bulletin 16 Section 18. All manufacturers produce to these standards here in the USA. There also is a size 6 and 7. Size 7 is rarely used in cap form. The charts below show data for RWMA caps and full size electrodes.

Page 42 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.