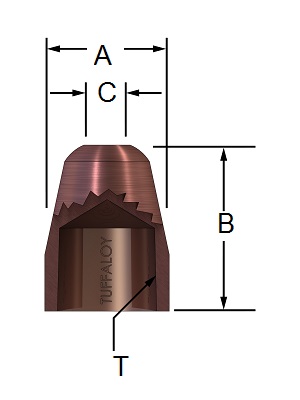

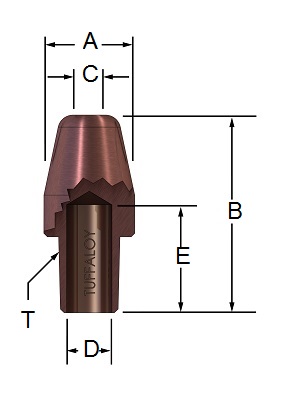

FEMALE CAP "A" Nose MALE CAP "A" Nose

Resistance welding caps both female and male are usually used in high volume and automated applications. In press welders resistance welding caps and shanks are frequently used to reduce copper electrode costs.

A male resistance welding cap is differentiated from a female by the male attachment taper that extends from the body of the electrode. In a female resistance welding cap the attachment taper is internal to the body.

Female and male resistance welding caps are functionally nearly identical. Males have a little more copper and therefor cost slightly more but may last a little longer since there is more copper in the head. By design there is more water flow contact with the male cap than the female cap. Proponents of male caps expect longer life than from female caps. Supporters of female caps do not believe you can recoup the cost differential of a male cap in weld life. Cap removal and dressing tools are available for either style. There are more female caps used in the marketplace than male caps.

In most cases the decision of female vs male is determined by preference or familiarity. It would be a very large move to change an entire automated facility from one style to the other. It is not just the caps but shanks or adapters, gun arms, dressers, removal tools and other items that would have to be changed. A change over should only be considered when new lines are brought in. Testing on off line equipment is the best way to evaluate the comparison of the two styles.

Reference: RWMA Resistance Welding Manual 4th Edition