Spot Welding

Questions and Answers

Part fit up is very important in determining the quality of resistance welds. All weld schedules call out a force value with the purpose of holding the part together, containing the weld nugget and performing a little forging as the weld cools. If the part does not fit up properly then part of this force is used to force or form the part into place and is not available to contain and forge the weld nugget.

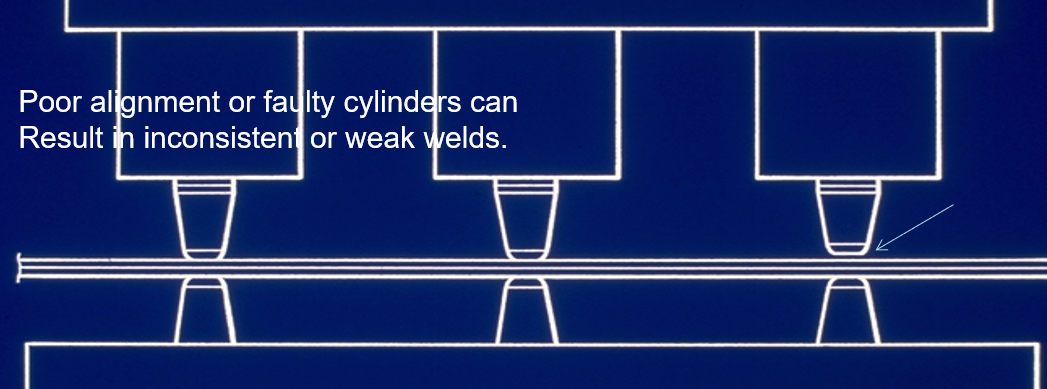

ALIGNMENT, FIT UP & WORN CYLINDERS CAN CASUE PROBLEMS

Burrs on the edges of stampings can cause problems because they prevent the part from seating properly or the burrs can break off and become particles which can be expelled during the welding operation.

Dirt, oil, burrs or scale on the surface of the parts being welded can affect resistance welding. They can cause expulsion from the surface, the interface or cause defects in the weld nugget.

If one alters the weld time from the desired range and exceeds the extreme either too long or short you risk surface expulsion, electrode mushrooming, and excessive indentation. If weld times are short you risk small nuggets and low weld strength or no welds.

Improper weld current selection can cause problems during resistance welding. The problems normally show up in the form of expulsion, indentation, electrode sticking, mushrooming or low weld strength. There is an ideal current range for every resistance weld set up. This will produce good weld nuggets with little or no expulsion, modest indentation and minimal electrode wear or sticking. Whenever you push the extremes of the current in the weld window either high or low you risk problems.

Page 38 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.