Part fit up is very important in determining the quality of resistance welds. All weld schedules call out a force value with the purpose of holding the part together, containing the weld nugget and performing a little forging as the weld cools. If the part does not fit up properly then part of this force is used to force or form the part into place and is not available to contain and forge the weld nugget.

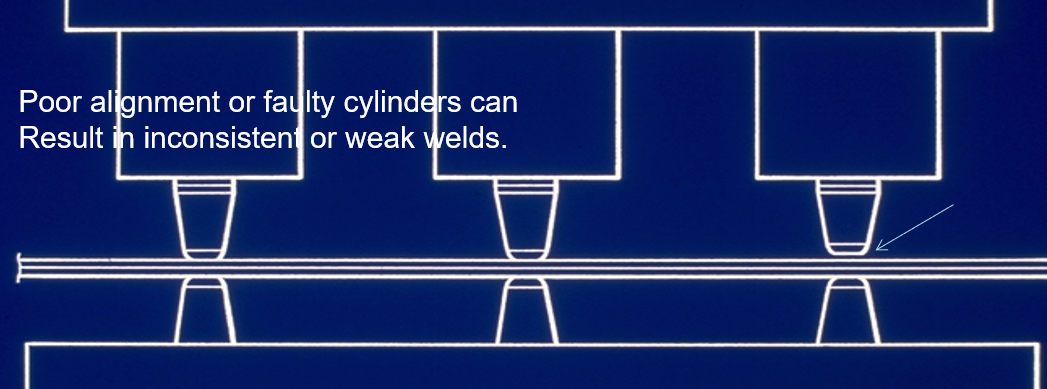

ALIGNMENT, FIT UP & WORN CYLINDERS CAN CASUE PROBLEMS

In multi weld operations where several welds occur simultaneously, the welds being held properly could be fine while the others may expel metal or not form good nuggets due to insufficient electrode force. The results will be inconsistent at this weld station and you will wonder why. The problem may trace back to a fit up problem.

Reference: RWMA - "Resistance Welding Manual 4th Edition"