Resistance welding electrode sizes are determined by referring to published weld schedules and looking up the recommended electrode size. Resistance welding electrode size is determined by the electrode body diameter and the electrode face diameter. These are determined by the work piece being welded and the forces and currents being used to develop a proper weld nugget.

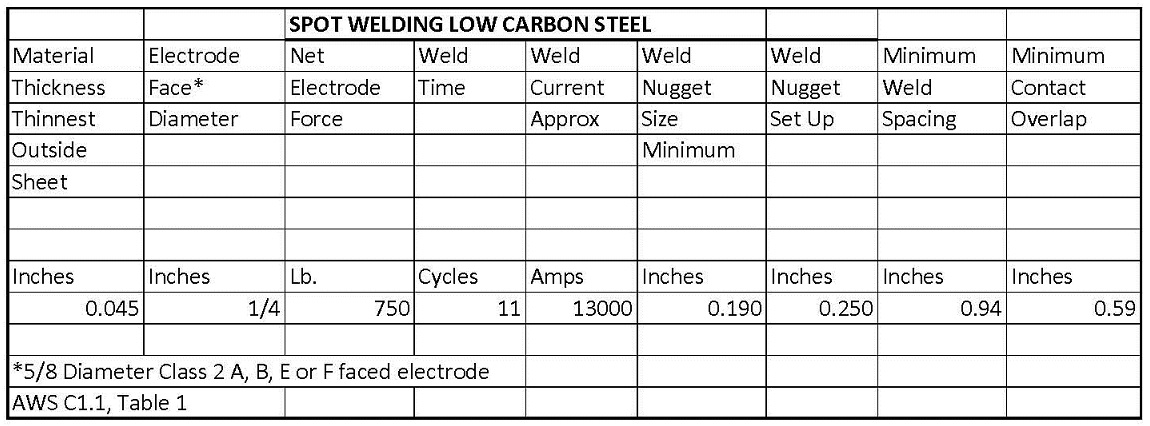

The first decision is to determine your governing metal thickness which is the thickness of the thinnest outside sheet of metal in your part stack up. Based on the governing metal thickness you use a weld schedule which can be found in:

AWS Standard C1.1 – Recommended Practices for Resistance Welding or the RWMA Resistance Welding Manual.

Using the C1.1 chart and a governing metal thickness of 0.045” on bare steel you will need an electrode with a face diameter of 0.250”. The suggested nose configuration is A, B, E, or F. Use what is normal for your plant unless your application design has a need for one of the others. Your electrode supplier will always be able to help with your electrode selection.

Reference: AWS Standard C1.1, Recomemded Practices for Resistance Welding