Spot Welding

Questions and Answers

Electrode sticking to the work piece generally is caused by excessive heating between the electrode and the work piece. In the Relative Resistivity Diagram RC has become too large. Any factor which would cause this is an issue that must be addressed to prevent this manufacturing problem. In many cases this condition is accompanied with excessive surface expulsion.

Electrode face mushrooming is the normal wear mechanism of a spot welding electrode. To slow this process or prevent excessive mushrooming one must control several factors in the welding process.

EXTREME MUSHROOMING

Resistance welding over a lip, in a corner, or in a box might be a perfect application for a double bend electrode.

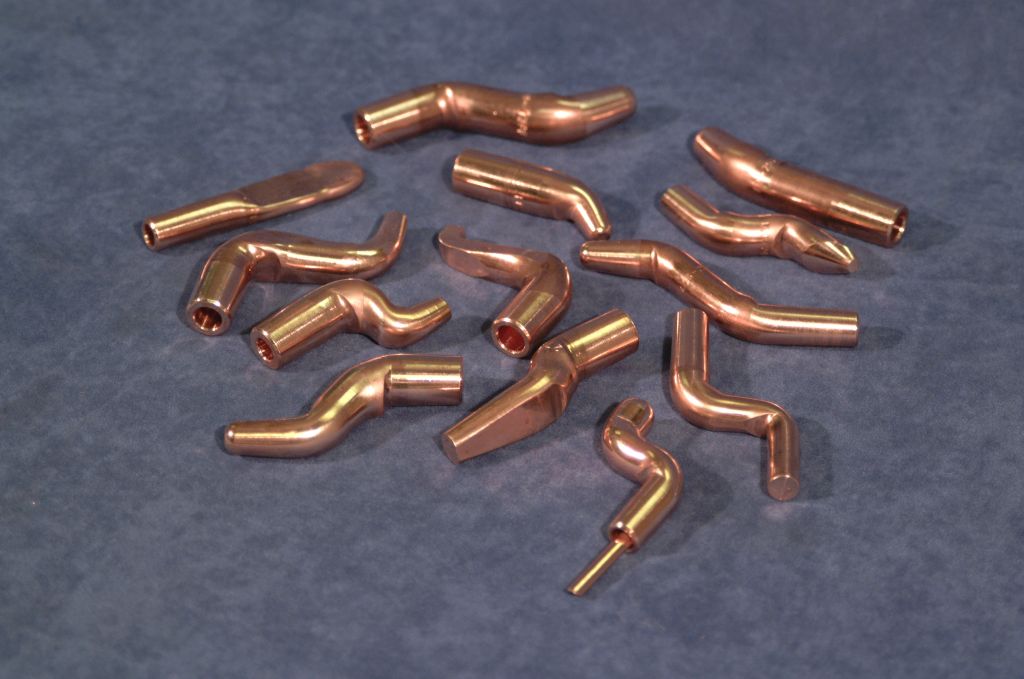

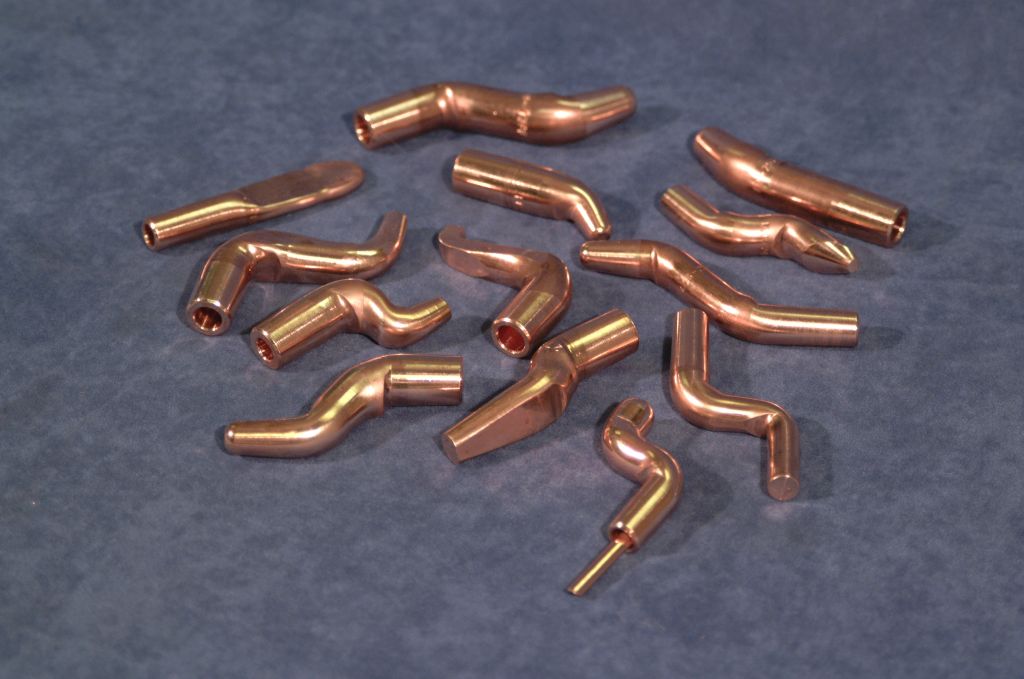

Above is a sketch showing an example of a double bend electrode welding in a tight area. There are many applications like this that a double bend full size electrode or double bend shank and cap will allow you to reach an otherwise difficult location to weld. Double bends can be water cooled to increase life. Double bends come in many offsets and sizes as shown below.

DOUBLE BEND ELECTRODES

Reference: RWMA - Resistance Welding Manual 4th Edition

SINGLE AND DOUBLE BENDS CAN REACH THAT EXTRA DISTANCE IN RESTRICTED AREAS

Sometimes we have to reach inside a box or over a feature in a part that stretches our imagination. A double bend electrode might be the answer but a single bend electrode might also get us that extra distance. Both can be water cooled and deliver good force into restricted areas.

Reference: RWMA - Resistance Welding Manual 4th Edition

Electrodes are available in many sizes and shapes to fit most needs in industry. To choose many considerations come to mind. The first decision would be full size vs cap electrode. Are you a job shop or highly automated usually decides this.

Page 40 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.