Spot Welding

Questions and Answers

When welding galvanized and other coated materials a layer of oxides and brass builds up on the face of the electrode. During the first twenty five to fifty welds while this layer builds up and develops equilibrium, the welding results can be inconsistent. This period is called conditioning.

EXTREME MUSHROOMING

All spot welding electrodes mushroom during use and when this happens the resultant weld eventually is unacceptable. Before this happens most operations either dress or change the electrode to get the face back to original operating conditions.

EXTREME MUSHROOMING

Some resistance welding applications call out forces above the limits of tapered electrodes. The RWMA Manual Fig 18.3 shows force vs taper. It shows that above 2400 Lbs force tapers are not viable. Above this force specially designed High Pressure/High Force Electrodes must be used. These electrodes can be straight shanks, threaded or flanged electrodes. They are available from several manufacturers. Contact your electrode supplier for assistance.

Reference: RWMA Resistance Welding Manual 4th Edition

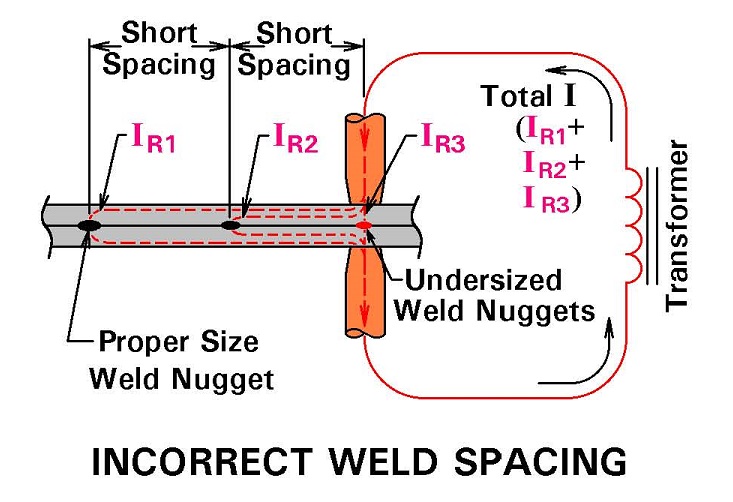

Yes, there is a minimum spacing for spot welds listed in most sample weld schedules. If welds are placed too close together, the weld current can flow through/across the sheet of metal between the desired weld and previous weld locations as shown. This current does not flow through the desired weld joint and therefore does not help create a nugget. This is called shunting current. It is wasted energy. In the figure below the first nugget is acceptable the second and third welds get smaller due to the shunting currents shown. The third weld is undersized in this example. The severity of this condition depends upon the material, parts, spacing and weld schedule.

Too correct for this increase the spacing between welds. Highly conductive materials like aluminum need larger spacing’s than more resistive materials like steel.

A weld schedule is an instruction of how to set up a resistance welder for a specific job. It includes all of the specific settings of the machine, control settings, tools, electrodes, forces, times, and rates and all other pertinent data related to a job. This information is stored and used to set the job up the next time you run it. It can be used as a ground zero if parameters have changed and you want to go back to where you started.

Page 41 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.