Spot Welding

Questions and Answers

All suspended gun systems consist of potentially four components that may require water cooling. They are the control, the transformer, the secondary cables and the electrodes with their copper holders. The traditional suspended gun systems would have all of these components. Newer systems may use transguns, which would eliminate the secondary kickless cables.

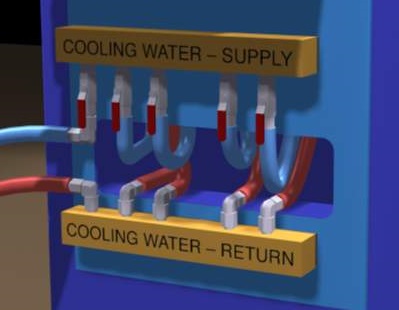

Depending upon your system, an input and output water manifold would be assembled similar to the one shown below. The output and input water lines would be routed to the components that require water cooling. The plant water supply would be connected to the supply side of the manifold. This could be city water, plant water tower system or a chiller. The return would connect to a sewer drain, water tower return or chiller return.

WATER MANIFOLD

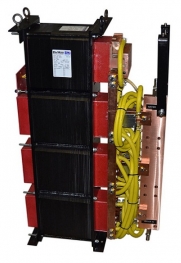

A DC transformer in this case refers to the traditional 50/60 Hz three phase transformer used for many years for high power requirement. These low frequency transformers are high power machines capable of long duty cycles. These tend to be large transformers due to their power ratings and applications.

DC LOW FREQUENCY TRANSFORMER

Burrs inside a tube could be formed by several resistance welding operations. It could be butt welding longitudinally to form the tube. It could be spot or projection welded to attach some lead or bracket to the tube. It could be an end closure weld to seal the end of the tube. Let’s look at these one at a time.

An inquiry came in asking why is MID FREQUENCY WELDING called MID FREQUENCY? That is a very logical question which goes back to the frequency of the power being generated in MID FREQUENCY resistance welding. In much of the world this is 1000 Hz.

In the world electricity frequency is divided into ranges of:

LINE FREQUENCY: This is the normal power grid in the world which run as 50-60 Hz

MEDIUM: 600Hz – 4000 Hz

High: 10 KHz – 50 KHz

The resistance welding inverters produce a 1000 Hz Dc output which is in the medium range which is why it is called a Mid or Medium Frequency welding.

If one looks beyond the electrical world we find that :

Speech and Sound have a similar break down and description of frequencies.

Lowest Sound Ear can detect - 20 Hz – 250 Hz

Mid Frequency (Human Voice) – 250 Hz – 4000 Hz

High Frequency (Cymbals) – 4 KHZ-20 KHz

Radio Waves have a similar but different range:

Low frequency is 30kHz to 300 kHz

Medium Frequency 300kHz to 3 MHz.

High Frequency 3 MHz to 30 MHz

VHF (Very High Frequency) 30 to 300 MHz.

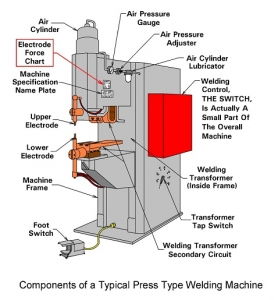

Manuals are supplied with a new resistance welder for the major components of the machine. If this is an old in house machine or a used machine manuals may not be present. In that case a thorough search of the machine to find the machine builder label with model number and serial number (if present) is in order for all of the components.

A weld gun would have the same information on it's components.

Page 27 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.