Spot Welding

Questions and Answers

In North America the common unit of measure for force is pounds (lb). AWS publishes force in units of Kilo Newtons (kn) and pounds (lb). Of course other parts of the world and even N America may use different but equivalent units of measure.

All of these force units (lb) may be converted into pressure units (psi) based on the area the force is being applied to.

Many electronic force gauges measure force and have the ability to read in the unit of measure desired.

DIGITAL FORCE GAUGE

Pressure and Force are frequently confused in resistance welding. They are related terms. The force applied produces pressure at the face of the electrode. For example approximately 1600 lb-force will produce 32,000 psi/pressure on a ¼” electrode face.

Reference: AWS C1.1- Recommended Practices for Resistance Welding

TUFFALOY CATALOG, Rev 2017

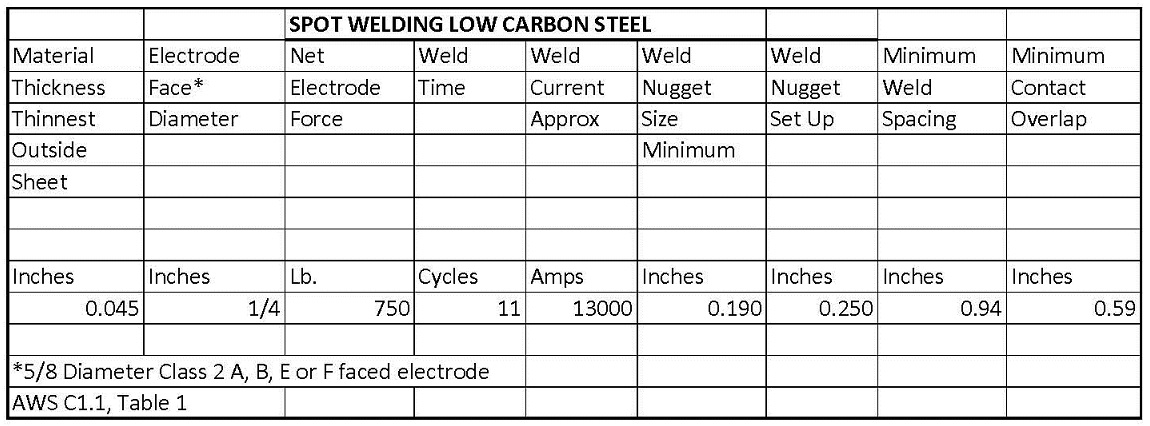

In this scenario we will base the schedule on the governing metal thickness (GMT– the thinnest outside sheet) , which is 1mm. For simplicity there was a chart readily available at 0.045 in material, which is 1.15mm.

This AWS C1.1 schedule calls for a 1/4inch weld face, 750 lbs force and 13000 amperes for 11 cycles.

Since the materials are dissimilar in thickness adjustments will need to be made to balance the heat and get the nugget to form evenly at the interface. This heat balancing is done with electrode face changes or electrode material changes. One wants to cool the thick side to move the nugget toward the thin material. Or you can heat the thin sheet.

For additional information see article:

What is poor heat balance in resistance welding?Reference: AWS C1.1 Recommended Practices For Resistance Welding

All spot welding electrodes wear in the same manner. They mushroom - The nose diameter grows larger with use.

SEVERE MUSHROOMED ELECTRODE

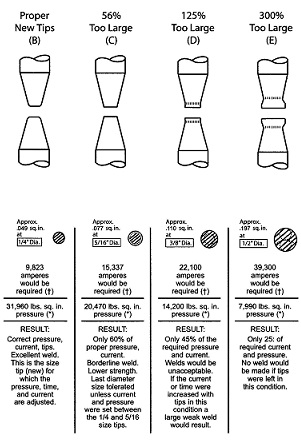

The mushrooming does not change the schedule or settings of the welder but it does change the path the current takes into the part. The contact surface area grows as the electrode face grows. Therefor the same current is spread over a larger area and the weld zone is not as concentrated and cools down. The current density has reduced. With time the weld strength reduces and will fail to meet quality standards unless corrective measures are taken. The chart below demonstrates the change in electrode face versus current requirements.

There are two methods to correct for this wear. One is to use the control to make regular increases in the current to match the face increase in size. The amount and frequency of these changes is developed by trial and error. If is usually a couple of amps each weld or several amps every 50 or 100 welds.

The other method is to dress (remachine) the electrode face back to the original diameter before it is too large. Then continue to weld. This can be done on the machine with automatic or hand dressers or remove and replace the worn electrode and reface on a lathe to return later to the weld line.

For additional information read Articles:

HOW DO I DETERMINE A TIP DRESSING FREQUENCY OR PROGRAM FOR A SPOT WELDING ELECDTRODE?

ON THIS SITE SEARCH FOR “DRESS”

Reference: RWMA – Resistance Welding Manual, 4th Edition

Pressure is one of the major component of the welding process Pressure, Current & Time (PCT). In most weld schedules pressure is called out as a force value. Pressure is this same value as force but applied to the surface area of the electrode contact face. See the article - How are force and pressure related?

Pressure is important because it provides the necessary mechanical force holding the two or more surfaces together during the welding sequence. This insures a good current path and contains the molten metal that may form to prevent expulsion. During the hold/solidification sequence the pressure/force provides a forging action which can strengthen the weld nugget.

Additionally changes in the force value up or down can change the heat generated in the part due to the change in the contact resistance. For example, more force means better contact and less contact resistance. The electrode contact face will run cooler. This can create or reduce electrode face wear or sticking and shift heat balance toward the part interface. Indentation may also be reduced. The opposite can be done with less force.

When seam welding a lap seam or a mash seam weld just as in a spot weld generally some amount of material is displaced along the edge of the wheel as it travels along the material. The amount and shape of this material or weld flash could be of sufficient amount to be considered a burr. The material we are talking about is the same material formed around the nose of a spot weld electrode as it welds. All resistance welds seam or spot can leave some deformed material around the periphery of the weld zone. This upset or forging contributes to the strength of the weld. Generally this is not enough to be called a burr but in some cases the indentation could be cosmetically offensive if the surface were to be subsequently painted or were in a very visible location like the hood of a car. Product designers avoid welds in these locations.

Where seam welds generate visible indentations or slight raised areas which are not desired, they can be treated as cosmetic welds. The weld schedule and electrodes, in this case weld wheels are selected to reduce the amount of heating and expulsion on the side of the part where the marking or burr condition is not wanted. The wheel weld face might be increased. The force may be increased. This reduces contact resistance and surface heating. Adjustments to current and weld speed can be made. All of these would be made with the intent of reducing the surface heat and amount of material being expelled or pushed out during the welding process.

Page 25 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.