Spot Welding

Questions and Answers

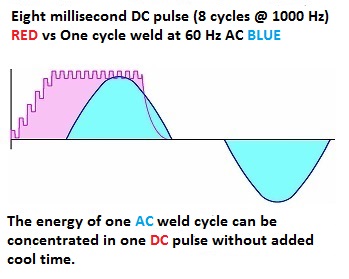

Medium frequency systems can vary from 600 – 4000 Hz frequency. Most resistance welding systems are manufactured in the 1000 Hz range. Mid frequency welding can offer many advantages including weight reduction, power reduction and cycle refinement. So one might ask would more than 1000 Hz be better. At this time there are a few applications resistance welding applications using frequencies approaching 2000 Hz. The use of these higher frequency appears designed to take advantage of additional equipment weight reductions realized on some sizes.

Units at all of these frequencies would offer weight reductions, power savings and the cycle refinement expected with mid frequency resistance welding.

At this time for economic reasons the preponderance of business remains at 1000 Hz.

Units at higher mid frequencies above 2000 Hz may be in the market but are not know to the author at this time.

Reference: RWMA - Resistance Welding Manual 4th Edition

If the resistance welding application is a high speed high power application requiring a lot of power, considerable cooling will be required. This is normally supplied by water systems in the form of city water, recirculated cooling towers or chillers. When cooling is critical due to unusual power and heat being generated attention must be taken to insure that:

Critical components are tested for adequate flow at the proper temperatures.

Water tubes are properly positioned

Chill block and all cooling channels are free of blockages

Chill blocks may need to have additional cooling channels

An upgrade from city or water tower to a chiller may be needed

Water flow meters should be installed and monitored on individual components

Yes, one could consider liquid nitrogen cooling. It is very cold, -195 deg C (-320 deg F). This extreme temperature is well below the 18-29 deg C (65-85 deg F) the AWS J1.2 recommended cooling temperature for a resistance welder.

Should one use liquid nitrogen cooling for resistance welding? Liquid nitrogen probably is not practical.

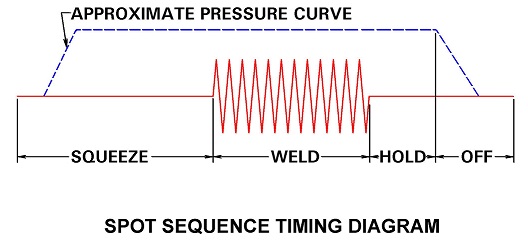

Squeeze time is the first function of the weld sequence during which the electrodes close on the part and build up full force before the control initiates the weld sequence. Squeeze time insures that the part is controlled and under the full force of the electrodes before amperage is applied. This contains the current flow to an area to heat, prevents flash and produces a good weld nugget.

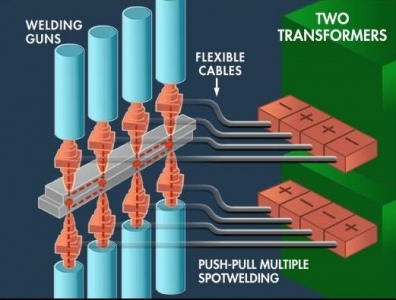

In push pull resistance welding two transformers are arranged opposite each other such that the opposing electrodes are opposite polarity and from the opposing transformer, as shown below. This arrangement is advantageous for making many spots in automated systems. All cables can either be above or below.

The question is how many SCR’s are required and how are they sized? In the above one SCR would control both transformers, fired at the same time. Therefor the sizing of the SCR would be based upon the total current draw and sizing of the two transformers making the four welds.

To size a transformer see article: “HOW TO SIZE A TRANSFORMER”

Reference: RWMA Manual- Fourth Edition

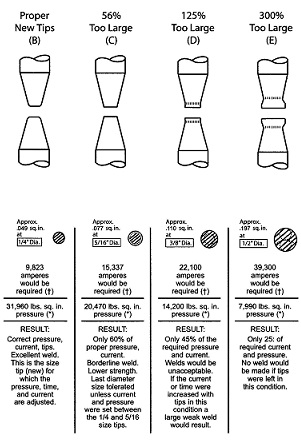

All spot welding electrodes will wear. It eventually appears in the form of mushrooming. To counteract this and keep the process going there are two options. One choice is to use a current stepper to match the face growth with small current increases every so many welds. The other choice is to dress the electrode face back to its original size before its growth has caused degradation in the weld quality. Without current increases the weld fails because the electrode surface area is too large for the current being used. The current density has dropped. The figure demonstrates this current density change.

ELECTRODE WEAR VS POWER

Page 26 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.