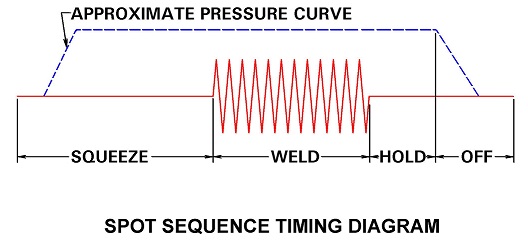

Squeeze time is the first function of the weld sequence during which the electrodes close on the part and build up full force before the control initiates the weld sequence. Squeeze time insures that the part is controlled and under the full force of the electrodes before amperage is applied. This contains the current flow to an area to heat, prevents flash and produces a good weld nugget.

There is no formula for squeeze time. It is determined by the equipment being used. How fast or slow the electrodes close and build up force? That determines how long squeeze should be. Some parts are large and the electrodes are open with a large travel distance while some only travel a short distance. Some shops dial in a few cycles and knowing that their equipment reacts slowly and will give them a few more cycles before the actual weld cycle will commence. Whatever the number, the weld nugget area needs full force to control the current flow and develop the proper nugget.

There is always pressure from the front office to get more parts out each shift. That means hold down all cycle times. Long squeeze times could reduce the parts per shift. Short squeeze times can produce inconsistent weld quality and weld flash.

Be prudent and choose the proper squeeze time and weld schedule that optimizes production and quality.

Reference: RWMA – Resistance Welding Manual 4th Edition