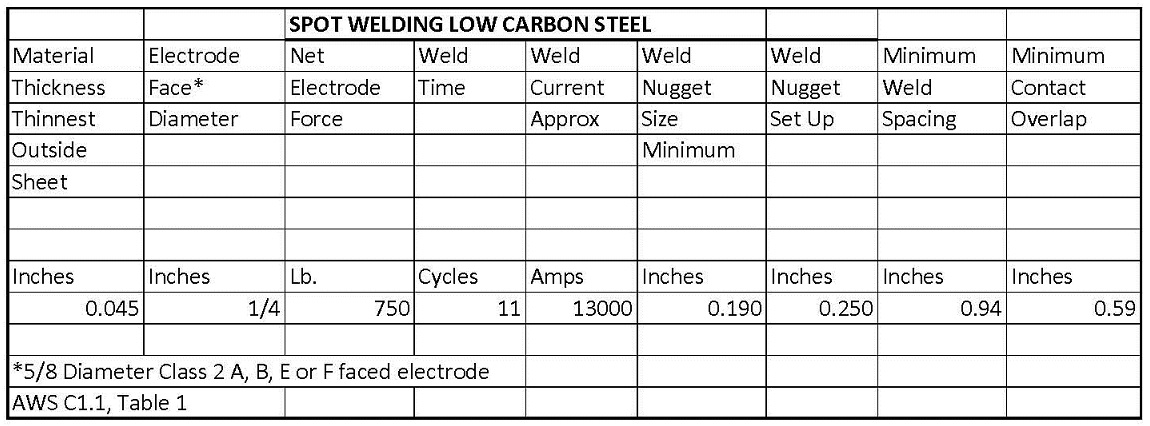

In this scenario we will base the schedule on the governing metal thickness (GMT– the thinnest outside sheet), which is 1mm. For simplicity there was a chart readily available at 0.045 in material, which is 1.15mm.

This AWS C1.1 schedule calls for a 1/4inch weld face, 750 lbs force and 13000 amperes for 11 cycles.

Since the materials are dissimilar in thickness adjustments will need to be made to balance the heat and get the nugget to form evenly at the interface. This heat balancing is done with electrode face changes or electrode material changes. One wants to cool the thick side to move the nugget toward the thin material. Or you can heat the thin sheet.

For additional information see article:

WHAT IS POOR HEAT BALANCE IN RESISTANCE WELDING

The issue of pressure vs force is they are directly related. Force is measured in pounds in the above schedule and the pressure applied is that same pounds applied to the ¼” weld face (pounds/in2).

Reference: AWS C1.1 Recommended Practices For Resistance Welding