Spot Welding

Questions and Answers

As long as the metal thickness, material and stack up are the consistant the same schedule can be used. This is an accurate statement with several exceptions.

First, the arrangement of the group of welds must be considered. All published weld schedules specify a minimum weld spacing to minimize shunting currents. Shunting current is current that can flow through the first weld rather than the weld being made. If the spacing is greater the resistance is higher and the current will not flow through the original weld. All of the current will flow through the desired weld area and produce a second good weld. If too close together more current is required to compensate for this wasted current.

Most published weld schedules list a value for minimum weld spacing between individual welds to prevent current shunting through the first weld.

This spacing will vary by the material and its thickness. Whether you are designing fixed automation or deciding the space between robot welds a minimum spacing must be adhered to for good weld practice.

The AWS recommended temperature range for spot welding cooling water is 65-85 degrees F. One should make a decided effort to stay within this range for the protection of the transformer and control.

The answer is YES. AWS Standard J1.2M/J1.2:2016 Guide to the Installation and Maintenance of Resistance Welding Machines

This standard covers installation as well as ongoing maintenance. This applies to welding guns or machines.

The spacing between welds is very important. If the welds are too close together some of the weld current could flow through the first weld. This current would be wasted and not help make the second weld. If less current flows through the second weld its weld nugget could be smaller than the first weld nugget.

Reference article: IS THERE A MINIMUM SPACING BETWEEN SPOT WELDS?

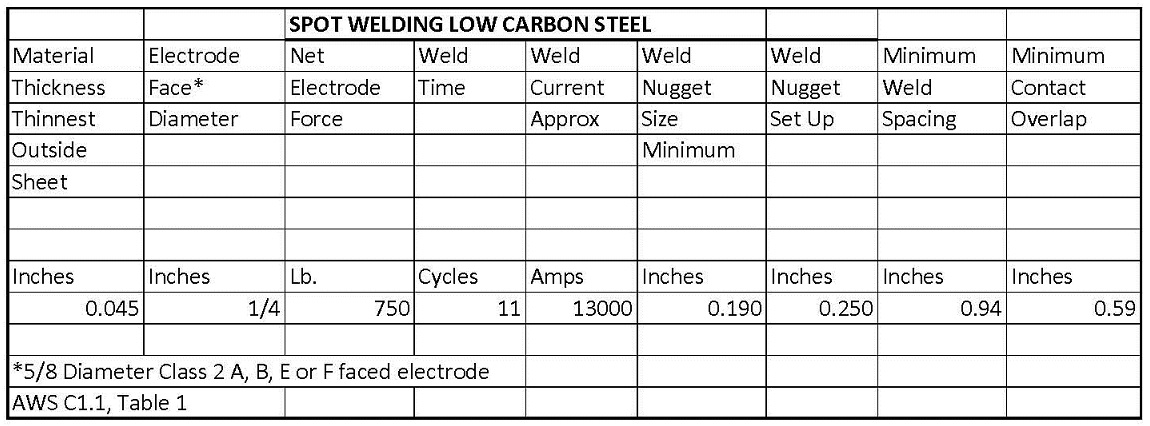

To determine the proper welding procedure for standard material one should turn to published weld schedules. There are schedules available for most common materials being resistance welded. The sample schedules give a good starting point. You likely will have to vary your settings to arrive at the desired quality values your job calls out.

Yes, a flat backup bar could be used to reduce indentation on the one side. It may be more prudent to use a large flat faced electrode on the side you would like to reduce indentations. A flat faced “C” nose electrode of the same body diameter as the electrode on the other side of the weld is commonly used. A larger diameter could also be used, for example a #5 flat face opposite a #4 pointed “A” nose. Of course if the tooling arrangement is easier to use a backup copper chrome (Class 2) bar that can accomplish the same goal.

Flat electrode or bar, the goal is to spread the heat on the good/no mark side of the part out over a large area. Using a smaller face on the other side will concentrate the heat on that half of the part. The nugget should form mostly on the non-show side of the part. Permit the weld nugget to grow into the good side only enough to make an acceptable weld. We are describing what is called a cosmetic weld.

Page 29 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.