Controls & Transformers

Questions and Answers

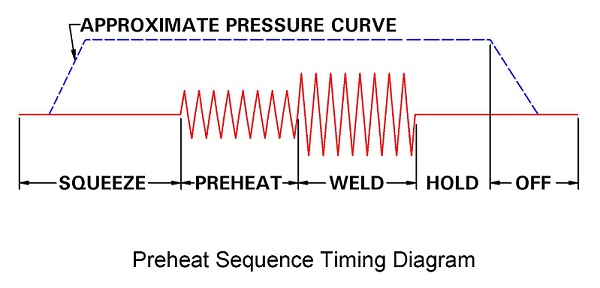

Squeeze time is the first sequence of a weld schedule. It is designed to allow the electrodes to close and build up full force on the parts before current is applied. If squeeze time is too long it does not hurt the welding operation but it does increase the cost of the total operation by increasing the total time of the weld schedule and thus fewer parts per shift.

Spot welding can decrease in weld size as you weld across the part. One cause for this is increasing magnetic material in the throat of the welder as you move across the part. Most parts are low carbon steel which is a magnetic material. In AC welding applications, if after each weld more material is moved into the throat of the machine, the weld current will decrease.

METAL IN THE THROAT CAUSES IMPEDANCE TO INCREASE

Cracks appearing in the parent material around the weld nugget can be caused by several issues. They are:

High Weld Force – can fracture the parent material with excessive forging action.

Insufficient Cooling – Over heating can cause excessive stresses from expansion and contraction along with the forging action.

Metallurgy of Material Welded – Some materials become brittle at the temperatures experienced in resistance welding.

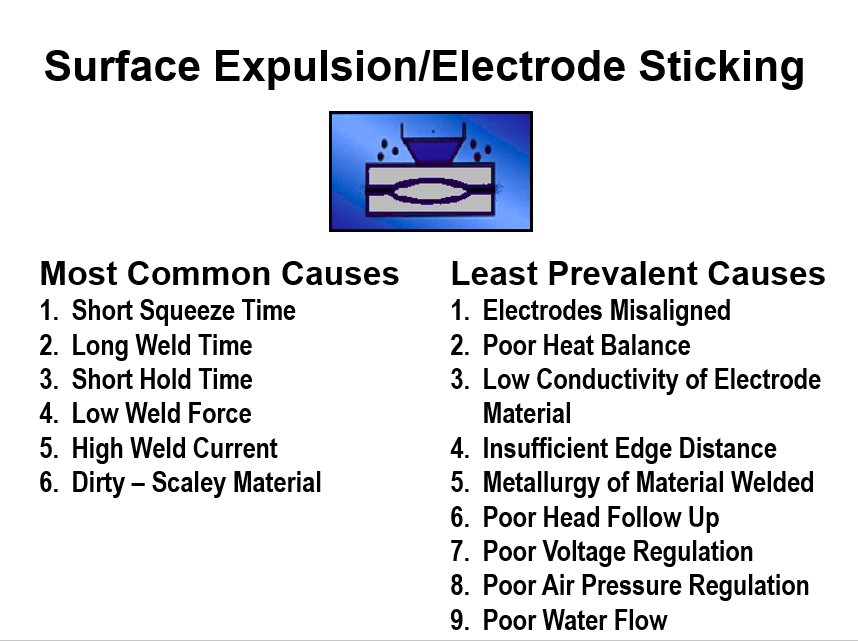

Surface expulsion is caused when the part surface heats up. So anything which would cause this, could be a reason. The appearance is similar to interface expulsion. In this case we are looking for conditions which cause the contact surface heat to be high.

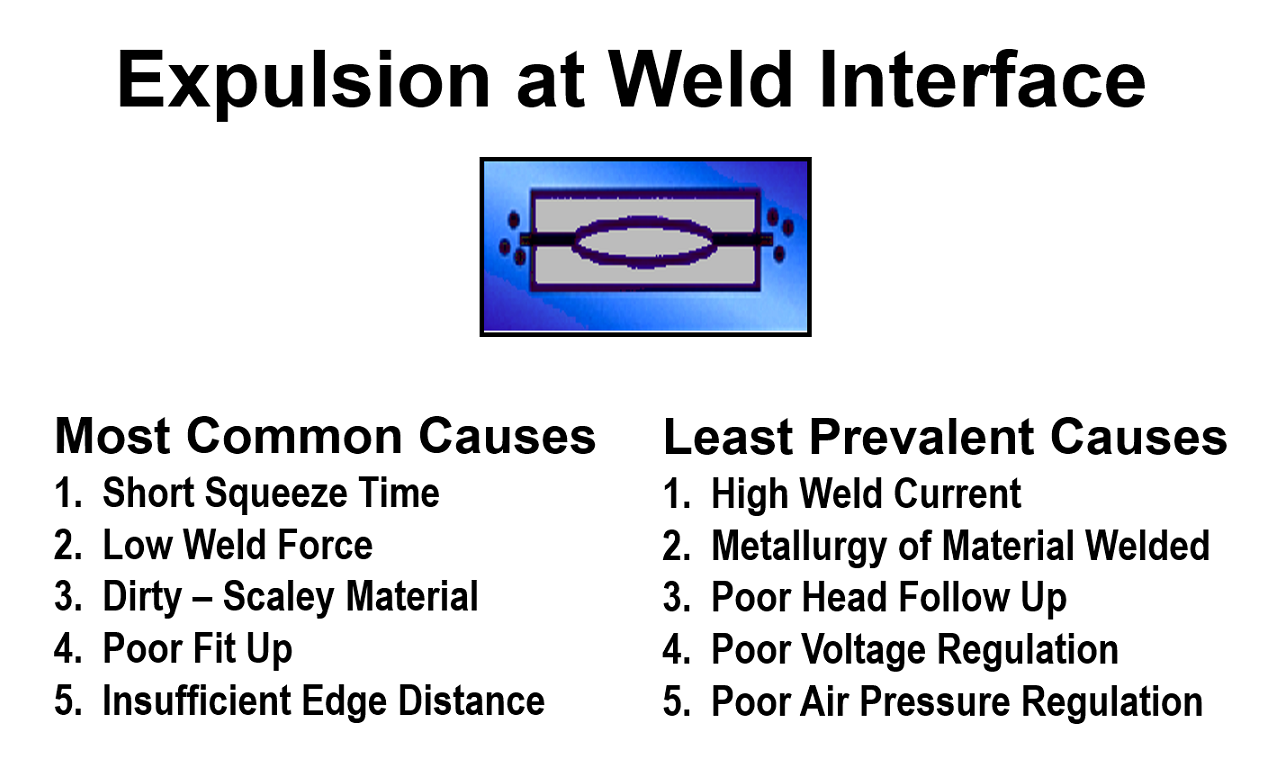

Expulsion of molten particles from between the two sheets of metal being welded can be caused by several items. All are related to causing excessive heat between the two work pieces or not containing the weld nugget during welding.

Page 33 of 39

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.