Controls & Transformers

Questions and Answers

Weld schedules are available in the Resistance Welding Manual and AWS Standard C1.1 for many of the most frequently used materials. The information commonly provided is the proper electrode design, size and material. The weld force, weld time and weld current are also published. The minimum distance between welds is usually listed and the expected nugget or button size is shown. Tensile properties frequently are also published. Other sources widely distfributed are the Tuffaloy and CMW Catalogs.

A weld schedule is an instruction to set up a resistance welder for a given job. It includes all of the specific settings of the machine, control settings, tools, electrodes, forces, times, rates and all other pertinent data related to a job. It also includes the information about the part, including material, thickness, number of welds, weld locations, quality requirements, and precleaning. This information is stored and can be used to set up the job on it’s next run. It also can be used as a ground zero if parameters have changed and you want to go back to when the job started.

Force is the "P" in PCT - Pressure Current and Time.The Force component of a weld schedule is required to hold the two work pieces being welded together during the welding operation. This prevents any arcing due to the parts being loose. If not held tightly molten material would be expelled during the weld operation. It also provides a forging action as the weld solidifies and cools. This forging action greatly improves the final weld strength.

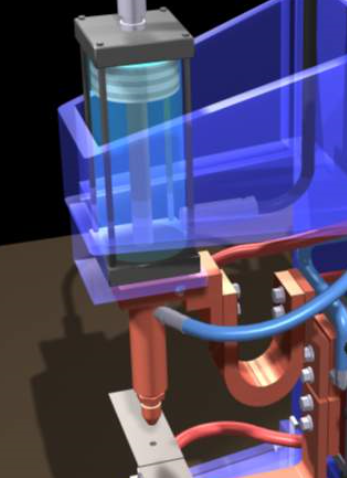

AIR CYLINDER

When a job is set up properly and the electrodes and water cooling are maintained it is still possible to have weld variation during a production day. It is very common that the line voltage at most production plants can vary during the day because of the demand on the Utility Company. The problem could be your feed to your plant or the Utility Company's main grid. It also could be overloaded power buses within the facility.

Air pressure is the reading on the pressure regulator that you set in order to deliver the desired force to the electrodes on the part being welded. Air volume is the ability to deliver this air and force within the time desired by the weld schedule. If the air manifold feeding the resistance welder cannot fill the cylinder in the squeeze time of the weld cycle you will be welding at a low force and in an uncontrolled condition.

Page 35 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.