Controls & Transformers

Questions and Answers

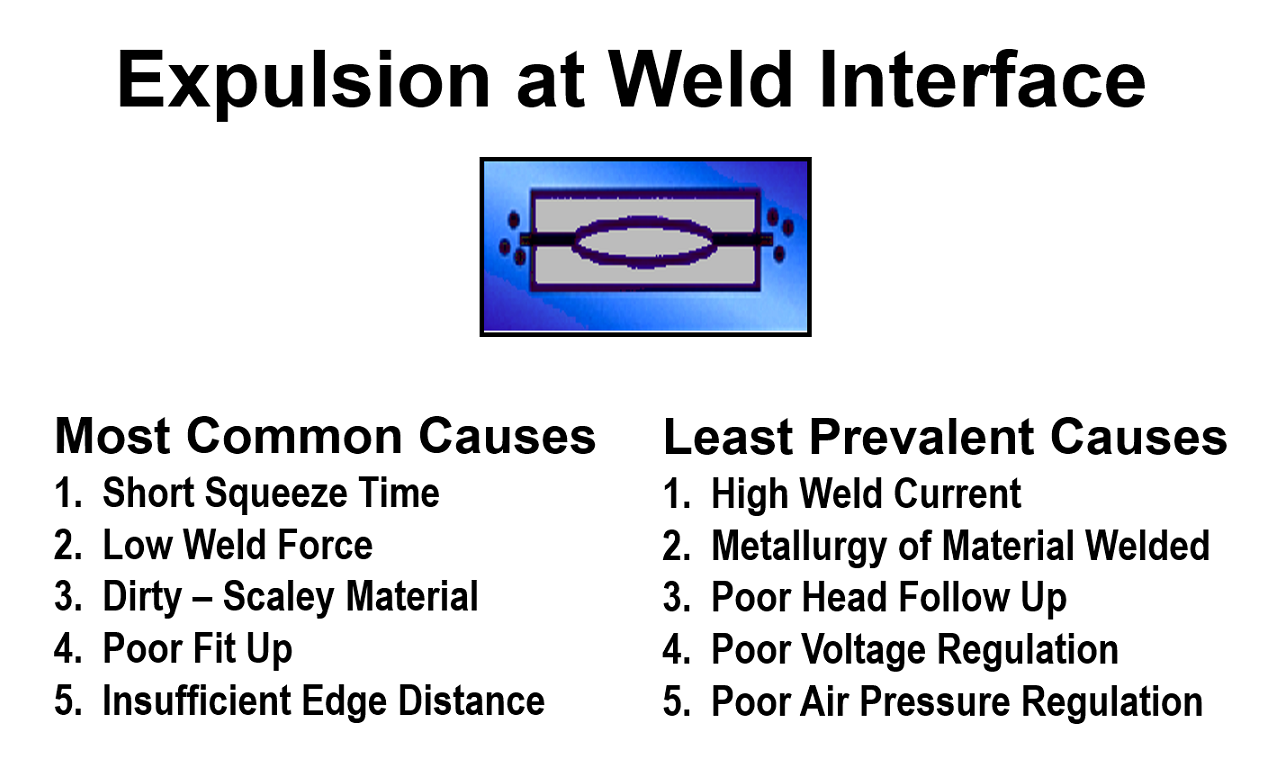

Expulsion of molten particles from between the two sheets of metal being welded can be caused by several items. All are related to causing excessive heat between the two work pieces or not containing the weld nugget during welding.

Force is one of the main inputs of the weld machine in the form of pressure exerted by the electrodes on the work piece. The main function of this force is to contain the weld by holding the work pieces together tightly during the welding operation. Stronger work piece materials require higher welding forces than weaker work pieces. With adequate force the contact resistance between the electrode and part is minimized and more energy is transmitted into the part to heat the interface between the two sheets being welded.

Pressure is one of the three major inputs of the machine, pressure, current and time. Pressure is called out as force in weld schedules. Force per square inch is pressure. When pressure is applied and the electrode makes contact with the part, there is a contact resistance at that joint. The amount of this resistance changes with the amount of force/pressure being applied.

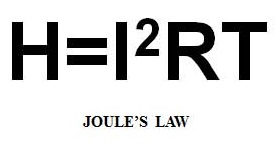

JOULES LAW STATES:

In this equation the current, resistance and time are the variables. The controller or timer can alter both the time and the current. The resistance of the parts being welded is fixed but the resistance can be changed by altering the force/pressure used in the welding process. The question is which will have the largest affect upon the process. The answer is the current (I).

Per the definition of the Resistance Welding Manufacturers Alliance:

RESISTANCE WELDING IS THE JOINING OF METALS BY APPLYING

PRESSURE

AND PASSING

CURRENT

FOR A LENGTH OF

TIME

THROUGH THE METAL AREA WHICH IS TO BE JOINED

Reference: RWMA - Resistance Welding Manual 4th Edition

Page 34 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.