Spot Welding

Questions and Answers

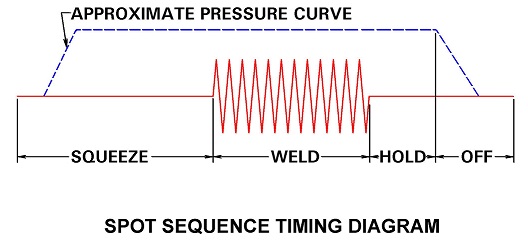

An inquiry came in after reading about PCT, It asked when does current flow? To clarify current flows during weld time. Be it AC, DC or MFDC equipment. Weld time is when the current is ON. The current is on the length of time T of PCT. The amplitude of the current is C of PCT. By now you know that the pressure or force is P of PCT.

To see and understand this better please view another article in this blog:

HOW ARE PRESSURE CURRENT AND TIME USED IN RESISTANCE WELDING?

Reference: RWMA Resistance Welding Manual 4th Edition

The answer is yes. One could, but it is not recommended. Stainless requires relatively high forces and pure copper without alloy strengthening additives does not have the strength at the temperature generated to hold up. Mushrooming will occur quickly. Weld nugget failure will be frequent and require constant electrode dressing and attention.

My answer is no don’t use pure copper. In another blog article electrode selection for stainless steel was addressed:

WHAT IS THE PROPER ELECTRODE MATERIAL FOR SPOT WELDING STAINLESS STEEL?

Stainless Steel weld schedules are available in:

AWS Specification C1.1 Recommended Practices for Resistance Welding

In this specification the data necessary to dial in a good starting weld schedule is available

Reference: AWS Specification C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition

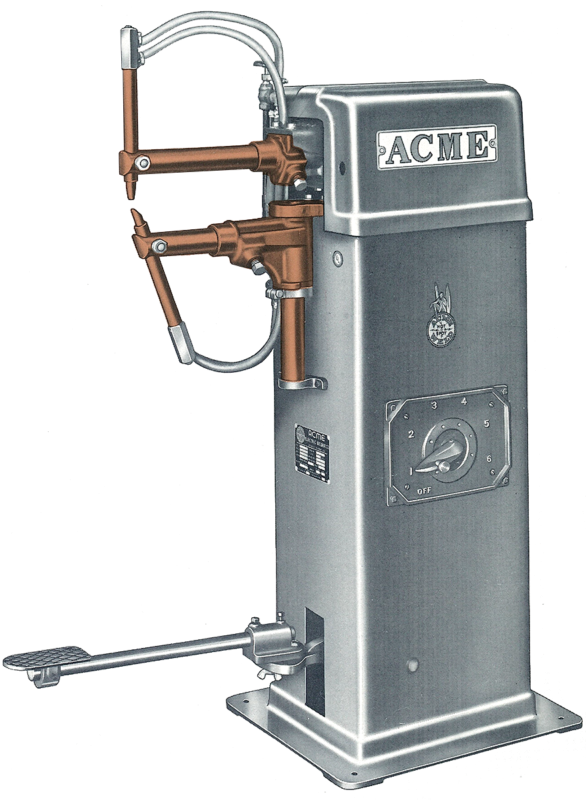

Job shops continue to have foot operated resistance welders in use. They are fewer but they are out there. The operators foot actually provides the initiation and force of the weld with leverage multipliers built into the machine design. To replace the persons foot a force mechanism must be provided. It must be capable of providing the force needed for the application.

FOOT OPERATED ROCKER ARM WELDER

To spot weld 1 mm (0.040 in) or 3 mm (0.120 in) steel a force of 3 Kn (700 lb) to 4.5 Kn (1000 lb) approximately might be used. A pneumatic cylinder which could produce that strength through the mechanical advantages built into the machine would be necessary. Stroke length would also need to be considered. These and other considerations can be discussed with local area Resistance Welding Machine Suppliers or Distributors. They will know the proper sources for the parts and information to make this conversion a success.

Machine design is beyond the scope of this discussion.

During nugget solidification the metal shrinks in volume and gases can be released at the same time. As this happens it is important that the part is held together under good pressure to prevent the joint from separating and failing but also to minimize voids. This is the hold time in the weld schedule. The force mechanism of the welder must be in good repair in order to be able to maintain constant force and follow-up as the material solidifies and shrinks. This is especially true with projection welds where the projections collapse.

The parameters to maintain for void reduction are:

Hold Time

Pressure Mechanism Maintenance and application

Forge application

Hold Time

Make sure there is hold time. Some schedules don’t allow hold time because it slows down the production rate. Hold is necessary to insure the faying surfaces are together until the nugget is solidified. In some applications it is used for void closure and forging or tempering.

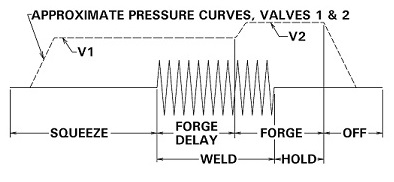

FORGE DELAY

Force is increased as the weld ends to forge the metal as it is solidifying to close voids. This is very prevalent with aluminum.

Pressure Mechanism Maintenance and Application

It is imperative that the pressure force system of the machine be in good working order. Be it cylinders or servo they must react when needed immediately with no delay or catches in their movement. Their ability to have good follow-up is important. This means they must move as the weld expands and contracts. This can be very fast. Remember welds are measured in cycles and milliseconds not seconds. A cylinder or servo that sticks is not acceptable.

Forge Application

The application of extra pressure or force during the solidification process is a very good tool to reduce voids. It essentially closes gas pockets and forges voids together. As shown in the figure above you may have to initiate this during the end of the weld cycle. Mechanical functions don’t react as quickly as electronic functions. This may take a little trial and error. If you squeeze too hard too soon the molten metal can be pushed out of the joint. Force may be the most important function to eliminate voids.

Reference: RWMA – RWMA Resistance Welding Manual 4th Edition

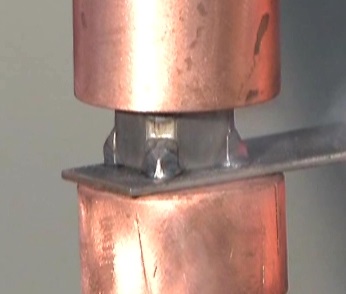

Resistance welding weld nuts is a projection welding process. In projection welding the part has been formed by design or shape to deliver the force and current at predefined generally small points, shapes or circles. In the case of weld nuts the power is delivered through several small points. Each projection will develop a normal weld nugget. This form of resistance welding uses the part to concentrate the heat and force not the electrode. The traditional weld cycle is squeeze, weld, hold. This is the same as a traditional spot weld. Preheats are not normally used in projection welds.

PROJECTION WELD NUT

Pre-heat is the initial application of current specified in the schedule. It is typically a constant value and a single pulse, although both of these can vary. It is also, by definition (Ref AWS A3.0), separated from the main welding pulse. A pre-heat is intended to alter the condition of the faying surface to be welded. The goal may be to help improve material fit, or aid in breaking thru a coating. Finally, the application of just the pre-heat pulse (or pulses) should not result in the joining of the parts together, either by melting and subsequent solidification, or the formation of a solid-state bond.

When considering the projection welding process, the passage of secondary current should only occur once the desired weld force has been achieved. However, once current does start to flow, all material through which it passes (shunts, cables, parts, etc.) are subject to resistive heating based on Joules Law, and that includes the projections themselves. So, what happens exactly? Dependent on the value and duration of the current, the projection geometry and the material they are made from, and the substrate type, gauge and coating, several possibilities come to mind. These include, but are not limited to:

• Nothing discernable happens: If the pre-heat current value or duration are too low or short, the conditions at the welding interface do not change, or at least they do not change much. Perhaps the projection geometry is not altered, or the other conditions at the faying surface (coating, etc.) are not affected. In the vast majority of cases, something is going to happen.

• Fusion of some sort is achieved: If the current value or duration are too high or long, one may have melting and solidification occur, or a solid-state bond is formed. As eluded to earlier, either outcome is not typically the desired consequence one would hope for with the application of just a pre-heat pulse. **

• The faying surface is altered without fusion occurring: With a more measured application of current and weld time, it is possible (among other things like breaking down the coating) to soften the projections such that the applied weld force will begin to alter their geometry. This alteration will most likely take the form of the contact surface of the projection increasing in size. In others words, the projections start to flatten. This is where things get just a bit interesting.

Once the projections start to flatten, their surface contact area increases. But what is the implication of this occurrence? At this point, it would be good time to take a brief look at one important and easily measurable aspect of resistance projection (and spot) welding - current per unit area. As the name implies, it is just the secondary current passing through the electrode contact face or projections, divided by their area. Once you start doing a bit of math on actual projection weld nuts for most steel grades (think M6 thru M10), numbers like 350-600 Amps/mm2 start to crop up. However, what if we increase the contact area of the projection, even by a little bit? While each case is unique, it may be possible to illustrate the issue with the weld nuts themselves.

For the sake of an example:

Let’s use an actual industry standard weld nut and see what happens when the contact area of the projection itself is allowed to vary within the stated tolerance - Forget the application of pre-heat. For this example, we will use an M8 three-projection weld nut. The projections are shaped like a truncated cone, which implies they have both a major and minor diameter. For this discussion, we will focus on just the major diameter.

The stated range for the major diameter is 4.0 – 4.3 mm. If we increase the size of the projections on one weld nut to the next from 4.0 mm to 4.3 mm we have a 7.5% increase in diameter, with a change of only 0.3 mm. The area at 4.0 mm = 12.6 mm2, and increases to 14.5 mm2 with the increase to 4.3 mm. The resultant area increase is 15.2%. If we were welding at 500 Amps/mm2, an increase in projection area as has been illustrated will result in the current per unit area falling to 434 Amps/mm2, a reduction of 13.2%. This is the same as decreasing the current from 20 kA down to 17.3 kA for a constant projection geometry. At this point, it does not take much imagination to realize what the potential outcome might be with dropping the current by over 13%, particularly when the heating associated with Joules Law is based on the value of the current squared. Finally, these types of geometry changes are more than possible when a pre-heat is applied to the Projection Welding process.

With the aforementioned in mind, it is easy to see how the application of pre-heat to a Projection Welding schedule can have some potentially profound effects on the projection welding process. Preheat should be used in both a judicious and methodical manner so that results can be quantified and the desired weld performance and quality targets are achieved.

Finally, please note I have not really mentioned the base material in this discussion. My rational is twofold 1) The application of a pre-heat to the Projection Welding process can have a significant impact to the projections themselves, irrespective of the base material type, and 2) The AHSS (Advanced High Strength Steel) specified in the question typically require Projection Welding schedules utilizing more force with shorter weld times and higher currents, and perhaps, a multi pulse approach. A pre-heat with these steels would not be advised.

**The concern associated with creating a bond during the application of a pre-heat (especially melting and solidification) is the resistance of the faying surface is potentially reduced to the point where the subsequent application of the main pulse of the schedule may no longer be able to provide enough energy to achieve the needed fusion. Projection welding is in essence a resistive heating process, and if we obliterate the faying surface by melting and solidification, our resistive component in Joules Law is greatly reduced, if not all but eliminated. This reduction may be enough that any further attempt at weld growth may not be possible, regardless of the amount of secondary current applied.

Reference: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4h Edition

Technical Input by - DONALD F. MAATZ Jr.

Page 7 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.