During nugget solidification the metal shrinks in volume and gases can be released at the same time. As this happens it is important that the part is held together under good pressure to prevent the joint from separating and failing but also to minimize voids. This is the hold time in the weld schedule. The force mechanism of the welder must be in good repair in order to be able to maintain constant force and follow-up as the material solidifies and shrinks. This is especially true with projection welds where the projections collapse.

The parameters to maintain for void reduction are:

Hold Time

Pressure Mechanism Maintenance and application

Forge application

Hold Time

Make sure there is hold time. Some schedules don’t allow hold time because it slows down the production rate. Hold is necessary to insure the faying surfaces are together until the nugget is solidified. In some applications it is used for void closure and forging or tempering.

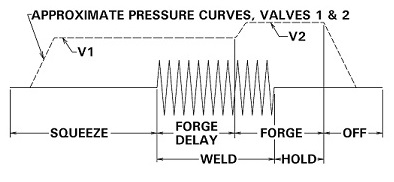

FORGE DELAY

Force is increased as the weld ends to forge the metal as it is solidifying to close voids. This is very prevalent with aluminum.

Pressure Mechanism Maintenance and Application

It is imperative that the pressure force system of the machine be in good working order. Be it cylinders or servo they must react when needed immediately with no delay or catches in their movement. Their ability to have good follow-up is important. This means they must move as the weld expands and contracts. This can be very fast. Remember welds are measured in cycles and milliseconds not seconds. A cylinder or servo that sticks is not acceptable.

Forge Application

The application of extra pressure or force during the solidification process is a very good tool to reduce voids. It essentially closes gas pockets and forges voids together. As shown in the figure above you may have to initiate this during the end of the weld cycle. Mechanical functions don’t react as quickly as electronic functions. This may take a little trial and error. If you squeeze too hard too soon the molten metal can be pushed out of the joint. Force may be the most important function to eliminate voids.

Reference: RWMA – RWMA Resistance Welding Manual 4th Edition