Spot Welding

Questions and Answers

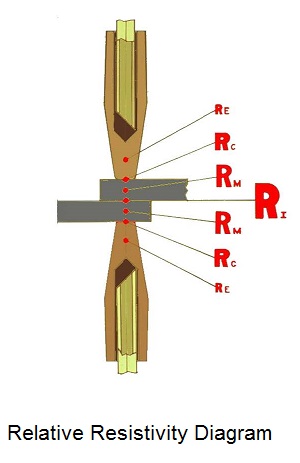

It is always best to spot weld to a clean surface. This means that preferably all oils and oxides would not be present in the weld interface. Any that are present will lead to interference with and an alteration of the contact resistance. In some instances, the dirt may be expelled as flash. Sometimes it merely absorbs energy and slows or alters nugget formation. Clean is good. Silicon Carbide clean is not desirable. It is a nonconductor. If it gets imbedded in the surface, surface resistance goes up and the heat distribution will shift and maybe make it difficult to conduct current consistently into or through the part. Three surfaces in the diagram can be affected. Two contact resistances Rc and the interface resistance Rx.

One wants to remove oxides and nonconductors not imbed new ones in the surface and leave them behind like silicon carbide.

A similar article on this subject is:

HOW CAN SANDBLASING AFFECT THE SURFACE RESISTANCE DURING RESISTANCE WELDING?

References: RWMA - Resistance Welding Manual 4th Edition

In the current market there are three systems used to deliver force on new resistance welders. They are air cylinders, air over oil cylinders and servos. In the marketplace I could probably find foot operated, cam and spring-operated devices still in use. New equipment is using cylinders and servos.

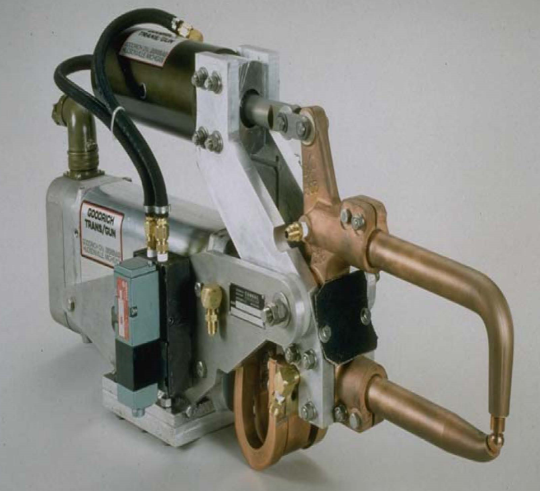

Pneumatic air cylinders have been around for many years and are well know in terms of design, capabilities and maintenance. They are used in all applications. They are noisy and require an air supply. In a large facility air has a cost.

GUN WITH AIR CYLINDER

Air over oil offers a soft touch and higher pressures in comparibly small cylinder sizes. Used for most applications including presses and weld guns. It does require both air and oil systems.

AIR OVER OIL CYLINDER

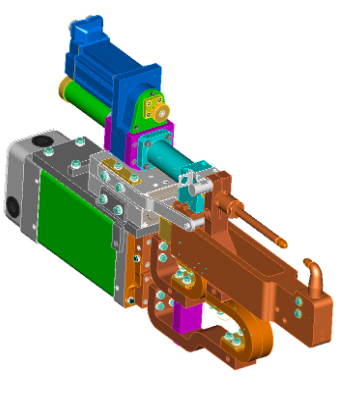

Servo offers computer style control, quiet and no need for large volume of air in the plant. Robotic systems have moved toward servos. Some press welders have used servos.

SERVO ACTUATED GUN

To learn why force is important in resistance welding see article:

WHAT IS THE FORCE COMPONENT OF A WELD SCHEDULE?

References: RWMA Resistrance Welding Manual 4th Edition

Some ARTWORK courtesy of Centerline

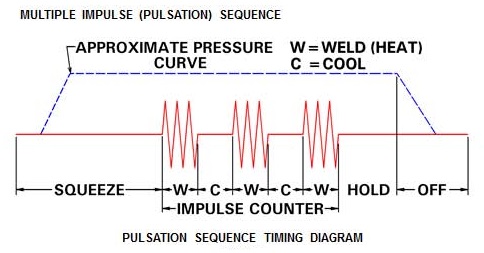

Pulses are used in resistance welding to help grow the nugget size without overheating the part. It is difficult to grow a nugget as large as the electrode face diameter or larger without being inventive with the weld schedule. Pulses or impulses are one means of obtaining nugget growth without overheating the part. There is always one or two off/cool cycles between each pulse.

Additional information on pulsation can be found in another article in this blog:

WHEN USING PULSATION IS THE SECOND PULSE SET HIGHER OR LOWER THAT THE FIRST PULSE?

Reference: RWMA - Resistance Welding Manual 4th Edition

WHEN USING PULSATION IS THE SECOND PULSE SET HIGHER OR LOWER THAT THE FIRST PULSE?Reference: RWMA - Resistance Welding Manual 4th Edition

On all welders the tongs should mate at the weld surface when the electrodes are attached. Altering the bend without or with heat might be a solution. Keep in mind the heat may anneal the tongs and reduce their strength. Good quality equipment has adjustments for alignment.

This is a machinery design/warranty issue not a resistance welding issue. It is not in the scope of this blog.

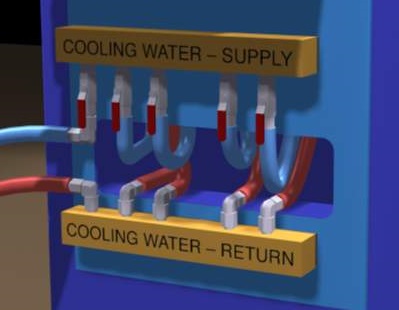

Many components in a resistance welding machine should see 4-6 L per minute (1-1.5 gal/min) of water. This is a very high necessary flow of cool water. The specifications for this water can be found in:

AWS Specification AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Proper sizing of the electric, air and water for a welder installation is very important. It should be done by professionals. The machine manufacturer may provide specifications for the installation. Contact local qualified installers.

This subject is beyond the scope of the blog.

Reference: American Welding Society - AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Page 6 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.