Hold is one of the three major sequences of a resistance weld schedule. It follows SQUEEZE AND WELD. The function of HOLD is to:

• Hold the welded surfaces together when the current is turned off

• Without hold expulsion could occur

• Hold acts as a heat sink and cools the part down to solidify the weld nugget under pressure

• The applied force acts as a forging action (Blacksmiths Hammer Blow). This force is a strengthening mechanishm for the weld nugget

• In some instances the hold force is increased to enhance this forging action.

• It can also close or reduce voids, and cracks in materials prone to this phenomena. Again part of the sterengthening that can occur.

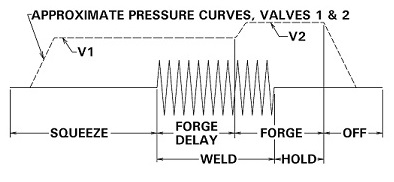

INCREASED PRESSURE TO FORGE THE PART

Operation without hold time runs the risk of voids, low weld strength or inconsistencies. Some operate with little or no hold time because machines have lag time in their response equivalent to a hold time. This is true but this may be compromising the blow from the “Blacksmiths Hammer” when the metal is hot.

Hold time has been discussed fully in several other articles in this blog:

What is Hold Time in a Resistance Welding Schedule?

Will Hold Time change the Resistance Weld Strength?

Reference: RWMA – Resistance Welding Manual 4th Edition