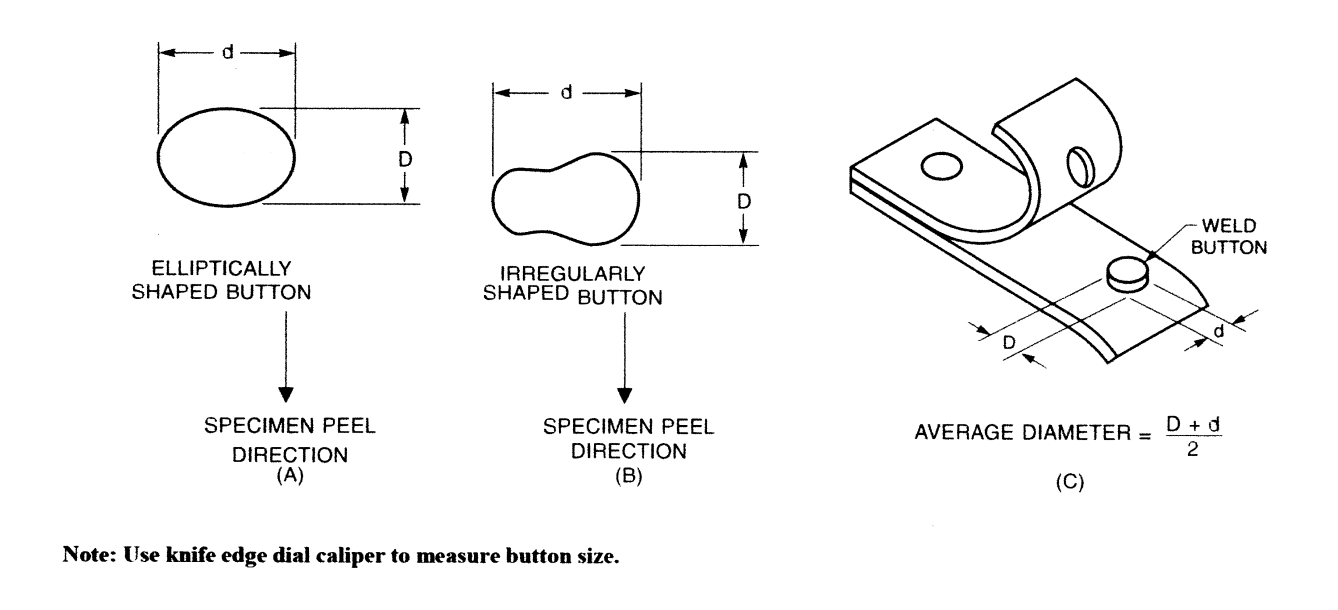

In most manufacturing operations nuggets are tested by pulling the part or test coupon apart after welding. This is frequently done with a combination of hammer, pliers and chisel. Then the resultant pulled weld nugget is measured with a set of calipers in two directions, 90 degrees apart. The two numbers are added together and divided by two for an average. This is the value to be compared to your quality standard. If the nugget is oblong or odd shape you still make the same measurement and divide by two getting the average over the varying dimensions.

This exhibits a “Coupon Test”. The actual part could also be tested in this manner.

Other test methods such as tensile testing and torsion testing may also be employed depending upon the application and quality standards.

Reference: AWS Standard C1.1 Recommended Practices For Resistance Welding