Quality of the resultant weld product is important to all producers. Testing of seam welds is very important. They are tested and monitored using methods similar to spot welding. The peel test where the part is destructively pulled apart to examine the weld nugget is very common. Coupons are frequently used to represent production runs with close monitoring or weld parameters. Tension shear testing of samples is employed in some applications. Leak testing is used for fluid tight applications. Metallography is also an option.

Continuous Seam Weld

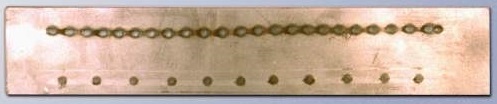

Roll Spot Welds

Reference: RWMA – Resistance Welding Manual Section 4

AWS C1.1- Recommended Practices for Resistance Welding