A seam welder is a spot welder using a wheel for an electrode. The shunting current rules apply the same for seam welding just as they do for spot welding. In the case of a traveling head seam welder the first issue is – How many wheels are mounted? Sometimes there are two. Their spacing/separation will be an issue to include. The next of course is the spacing of the spots. If this is a liquid tight seam weld then shunting currents will be present and must be allowed for. If this is a roll spot seam, the distance can be adjusted/increased to prevent shunting currents.

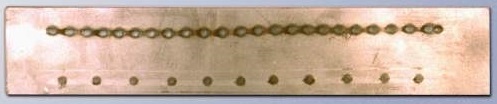

CONTINUOUS SEAM ROLL SPOT

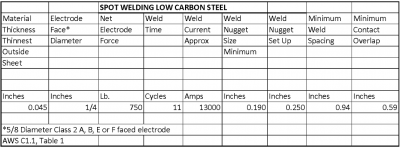

Yes, there is a minimum spacing for spot welds listed in most sample weld schedules. Shunting currents must be dealt with. If welds are placed too close together, the weld current can flow through/across the sheet of metal between the desired weld and previous weld locations. This current does not flow through the desired weld joint and therefore does not help create a nugget. This is called shunting current. It is wasted energy. The severity of this condition depends upon the material, parts, spacing and weld schedule.

Too correct for this, increase the spacing between welds. Highly conductive materials like aluminum need larger spacing’s than more resistive materials like steel.

Weld schedules are available that offer minimum spacing between spots. These values are designed to prevent shunting. The charts are available from many sources including:

AWS - Standard C1.1 Recommended Practices for Resistance Welding

If design is such that you must make the weld close together then you must use more power to compensate. Unfortunately you are driving all electrical components on the welder to higher levels and they will need additional cooling or off time to compensate.

Most published weld schedules list a value for minimum weld spacing between individual welds to minimize current shunting through the first weld.

This spacing will vary by the material and its thickness. Whether you are designing fixed automation or deciding the space between robot welds a minimum spacing must be adhered to for good welding practice.

Related Article: “IS THERE A MINIMUM SPACING BETWEEN SPOT WELDS?”

Reference: AWS C1.1, Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual

CMW Inc. Catalog

Tuffaloy Products Catalog