Information for seam welding stainless steel is published by the American Welding Society in their Welding Standards.

"AWS Standard C1.1:2019 “Recommended Practices for Resistance Welding”

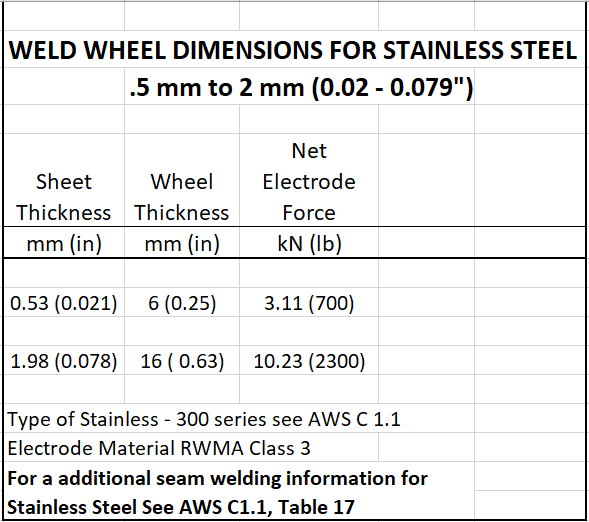

In this standard all the pertinent weld schedule information to make an initial set up is provided. This includes seam weld wheel material and wheel width for various thicknesses of stainless steel. For the bracketed sizes above the wheel information would be:

The weld wheel diameter will depend upon the product being welded and the wheel thickness. Some of the factors to consider are:

A very thin wheel would not be used in a large diameter.

The wheel diameter must be harmonious with the part dimensions and design. If a cylinder is being welded the one wheel must be a diameter that can fit into the cylinder. Other designs may have similar constraints.

Generally the two weld wheels are the same diameter.

The mass of the weld wheel helps in cooling the weld area along with the normal flood cooling.

If the wheel is being continually dressed, then larger diameter wheels mean longer run times before a wheel change is required.

Weld wheel extremes vary from a few inches (50 mm) in diameter to several feet (0.6m). Common wheel sizes are 10 -14” (25 – 40 cm). Wheels up to 24” (61 cm) are also common.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS Standard C1.1: 2019 Recommended Practices for Resistance Welding