Spot Welding

Questions and Answers

With no input on the process or materials many assumptions will be made in this analysis. First the control and transformer are of adequate size and are functioning properly. Second the material being welded is weldable and the parts have good fit up. The force system of the welder is in good working order.

Now we can address common causes for low weld strength:

Low weld strengths can be caused by material of low strength. This will not be considered. To have high weld strengths you need a good nugget generally of modest size as prescribed by published weld schedules. Smaller nuggets produce lower strengths. Anything that retards nugget formation or growth will reduce weld strength.

Another article in this blog describes the factors that affect nugget size and growth:

WHY DO I HAVE LOW WELD STRENGTH?

Reference: RWMA - Resistance Welding Manual 4th edition

That is an interesting question. The answer could be found in the equipment manual. The pendant could be faulty. Equipment design and function is beyond the scope of this blog.

Contact the manufacturer, local distributor or supplier for assistance.

One should always attempt to make a resistance weld under steady state conditions. If the desired pressure, current and time were applied consistently each weld, one can expect every weld to be the same weld after weld. If one of those three input varies then one could expect that the welds might vary. Rising pressure, loose cables, electrode issues, misalignment, faulty cooling or many other issues can and do affect the welding results.

If one has a robust process that is running well but you are pushing the limits on the pressure build up, remember to keep a close watch on the weld results. You may be taking advantage of the lag in the weld gun reaction and initiation speed. The machine does not react instantly and takes several more cycles before the electrodes are actually closed. You should always attempt to reach 90% of desired force before the weld is initiated.

However:

If one has something that works

It is a Robust process

It is monitored closely

NEVER ARGUE WITH SUCCESS!

Maintaining the proper pressure during a welding operation is very important to obtaining good welds and a long running operation.

Many articles have been written in this blog on the importance of pressure and force. They include:

Why is the control of pressure important in resistance welding?

How are force and pressure related?

How does pressure affect resistance?

HOW DO FORCE AND PRESSURE CONTAIN EXPULSION?

Reference: RWMA - Resistance Welding Manual 4th Edition

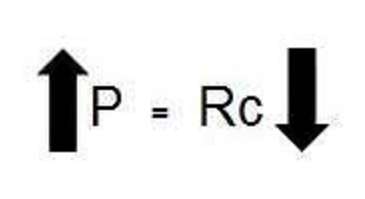

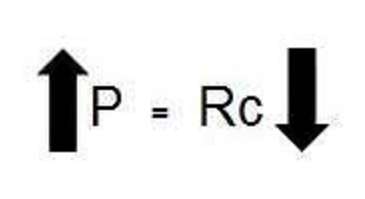

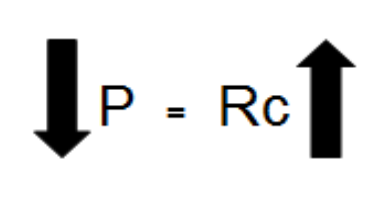

The subject of too much pressure/force has been addressed in several articles on the blog. Increasing the pressure reduces the contact resistance between the electrode and the part being welded. Less heat is generated on the part surfaces which effectively cools the part. Conversely less pressure creates more contact resistance and heat at the surfaces. The part will heat more.

INCREASING PRESSURE DECREASES RESISTANCE DECREASEING PRESSURE INCREASES RESISTANCE

A dent free spot weld can be defined as a “Cosmetic Weld”. This is a spot weld where one side of the weld would show little or no electrode indentation. The middle of an automobile hood would be a location where an indentation would not be desired. Medical instruments are another example. By the nature of the resistance welding process metal fusion and indentation are inherent features of the process. Control of the amount of heat and where it is applied is the path to producing a cosmetic weld.

Page 10 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.