One should always attempt to make a resistance weld under steady state conditions. If the desired pressure, current and time were applied consistently each weld, one can expect every weld to be the same weld after weld. If one of those three input varies then one could expect that the welds might vary. Rising pressure, loose cables, electrode issues, misalignment, faulty cooling or many other issues can and do affect the welding results.

If one has a robust process that is running well but you are pushing the limits on the pressure build up, remember to keep a close watch on the weld results. You may be taking advantage of the lag in the weld gun reaction and initiation speed. The machine does not react instantly and takes several more cycles before the electrodes are actually closed. You should always attempt to reach 90% of desired force before the weld is initiated.

However:

If one has something that works

It is a Robust process

It is monitored closely

NEVER ARGUE WITH SUCCESS!

Maintaining the proper pressure during a welding operation is very important to obtaining good welds and a long running operation.

Many articles have been written in this blog on the importance of pressure and force. They include:

Why is the control of pressure important in resistance welding?

How are force and pressure related?

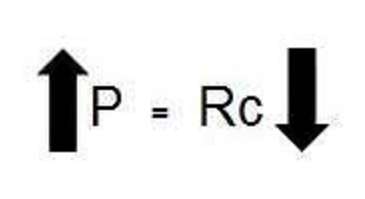

How does pressure affect resistance?

HOW DO FORCE AND PRESSURE CONTAIN EXPULSION?

Reference: RWMA - Resistance Welding Manual 4th Edition