Pressure is one of the three major inputs of the machine, pressure, current and time. Pressure is called out as force in weld schedules. Force per square inch is pressure. When pressure is applied and the electrode makes contact with the part, there is a contact resistance at that joint. The amount of this resistance changes with the amount of force/pressure being applied.

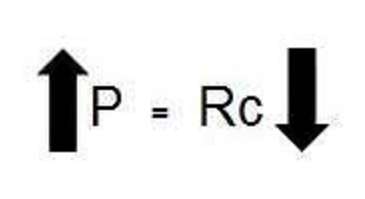

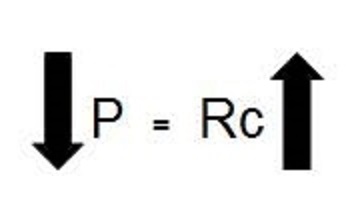

The relationship between pressure and contact resistance is inversely proportional. As the pressure goes up the contact resistance goes down because the electrode is making better contact with the work piece. Conversely if the pressure is decreased the contact resistance goes up due to less contact. As this resistance changes so does the heat being generated on the surface of the part. Lower forces heat the part surface and electrode face. Higher forces/pressures reduce this heating.

Other related articles in this blog are:

How will too much pressure or too little pressure affect the resistance weld?

Why is the control of pressure important in resistance welding?

References: RWMA - "Resistance Welding Manual 4th Edition"