Spot Welding

Questions and Answers

Hold is one of the three major sequences of a resistance weld schedule. It follows SQUEEZE AND WELD. The function of HOLD is to:

• Hold the welded surfaces together when the current is turned off

• Without hold expulsion could occur

• Hold acts as a heat sink and cools the part down to solidify the weld nugget under pressure

• The applied force acts as a forging action (Blacksmiths Hammer Blow). This force is a strengthening mechanishm for the weld nugget

• In some instances the hold force is increased to enhance this forging action.

• It can also close or reduce voids, and cracks in materials prone to this phenomena. Again part of the sterengthening that can occur.

It is very difficult to control the weld environment when welding upon a surface which has already been welded.

See other articles in this blog:

Why do seam welds over tack welds produce inconsistent weld, expulsion and flash?

IS THERE A MINIMUM SPACING BETWEEN SPOT WELDS

Each time that the welder closes the welding conditions needed are unknown. Is the electrode closing on a previous weld fully, half on, next to one or on virgin metal. This position variable changes the shunting current and thus the welding conditions. Maybe the electrode landed between two welds but the metal must be forced together which used up most of the available force. No force remains to contain the weld nugget during the weld cycle. Now we have shunting current problems plus lack of force. If the force is low the heat will be higher leading to a hot spot without containing force. This is a set up for expulsion.

Performing repair work can lead to a substantial amount of excitement and fireworks. It is not a controlled environment.

SEAM WELDING FLOOD COOLING

A resistance braze might be a better option in some cases. It requires heat but not as much. Just get the braze material hot and melted. There may be a braze paste that will do the job and fill in the voids? The resistance welder can generate the heat in the same manner just heat up slowly. Heat may be for several seconds not cycles.

See another article in this blog:

WHAT IS RESISTANCE BRAZING?

References: RWMA – Resistance welding Manual, Revised 4th Edition

In order to set up a machine or process to make good resistance welds many steps must be taken. They begin at machine installation and continue through the day-to-day operation. A good source for the installation information is:

AWS J1.2 “Guide to Installation and Maintenance of Resistance Welding Machines”

This document outlines the many basic specifications for air, water and electrical specifications. After these are established then one turns to the machine components:

MOUNTING SURFACES – Musts be electrically clean, perpendicular or parallel

ELECTRICAL CONNECTIONS – Clean and tight.

HOLDERS – Must be in good serviceable condition with good clean tapers

ELECTRODES – TAPERS AND FACES Must be in good conditions and proper size and not damaged with water tubes in the proper location.

WATER FLOW – Test water flow to all components

WATER TUBE LOCATION CONDITION – Check for electrode AWS J1.2

CYLINDER/SERVO MOTION FORCE DELIVERY- Evaluate force system with force gauge to confirm accuracy and watch for uneven motion or slow followup. Immediate followup is imperative for projection welding.

Nickel can be resistance welded. The question here is: can foil be handled and equipment sized to process it? The answer is - probably, yes. Equipment referred to as “Micro Resistance Welders” is used in industry to process very small intricate parts for medical, electronics, electrical and many other applications. The best place to find an answer to the above question will be on the web. Search for suppliers or users of micro resistance welders.

Weld nugget size and shape are dependent upon the welding parameters and the condition of the parts being spot welded. Electrode size, shape and location on the part can have an effect. The weld schedule which is the power input and force of the electrodes will affect nugget formation. The part material, surface conditions and flatness will contribute to the nugget formation.

Most weld schedules call out a desired nugget size. The welds can be cross sectioned and measured. The most common method is to pull the two welded surfaces apart to expose the nugget. This is performed with a vice, using pliers, hammer and chisel.

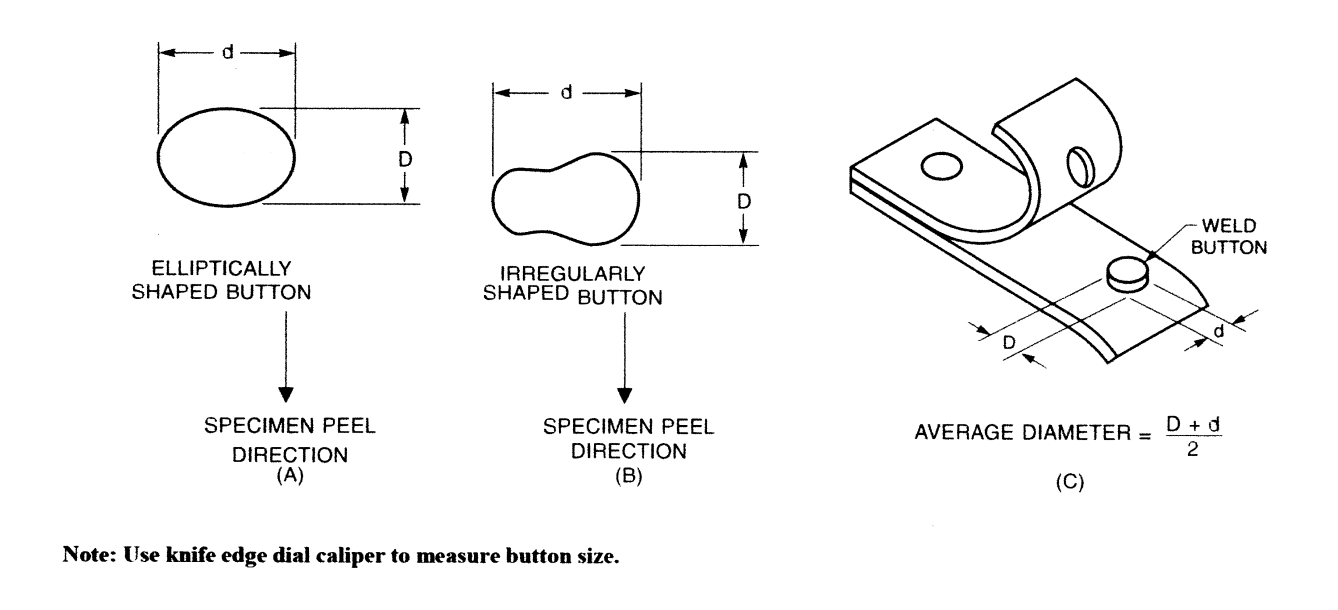

The result in graphic form is shown below:

The nuggets may not be perfect circles. To calculate the nugget size all are calculated using the same simple average of the dimensions as shown. Weld nugget size is the normal specified dimension. Weld nugget area is generally not specified. If desired the area is desired, it can be calculated

Using the area of a circle: A = πR2 or A = πD2/4

In the case of the “C” exhibit above this formula will work. For exhibit “A” or “B” the math becomes complicated. Every nugget can vary in shape and size as suggested by exhibit “A” and “B”, depending upon the weld conditions. Calculation of the weld area for these examples is a mathematics exercise. The possible variations too many for consideration in this blog.

References: RWMA Resistance Welding Manual 4th Edition

AWS Standard – C1.1 Recommended Practices for Resistance Welding

Page 8 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.