In order to set up a machine or process to make good resistance welds many steps must be taken. They begin at machine installation and continue through the day-to-day operation. A good source for the installation information is:

AWS J1.2 “Guide to Installation and Maintenance of Resistance Welding Machines”

This document outlines the many basic specifications for air, water and electrical specifications. After these are established then one turns to the machine components:

MOUNTING SURFACES – Musts be electrically clean, perpendicular or parallel

ELECTRICAL CONNECTIONS – Clean and tight.

HOLDERS – Must be in good serviceable condition with good clean tapers

ELECTRODES – TAPERS AND FACES Must be in good conditions and proper size and not damaged with water tubes in the proper location.

WATER FLOW – Test water flow to all components

WATER TUBE LOCATION CONDITION – Check for electrode AWS J1.2

CYLINDER/SERVO MOTION FORCE DELIVERY- Evaluate force system with force gauge to confirm accuracy and watch for uneven motion or slow followup. Immediate followup is imperative for projection welding.

Once the machine or weld gun is set up then we do the day to day running of the process.

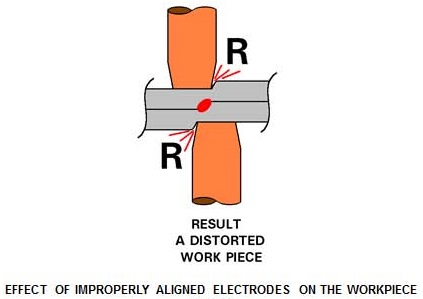

Spot welding electrodes have a large influence on the resistance welding process. Their alloy and face size contribute to the development of the proper weld nugget. All of this assumes that the electrodes have been installed properly. This means proper water cooling and water tube location and good alignment. Alignment means that the face of the electrode is square and parallel to the part being welded. In addition the upper and lower electrodes faces should line up vertically with each other. The goal is to apply all forces on the same central axis. This prevents the electrodes from imparting and twist or distortion into the part during the welding operation.

Electrodes aligned improperly sometimes skid on the workpiece during welding.

Reference : AWS - AWS Standard J1.2 “Guide to Installation and Maintenance of Resistance Welding Machines”

RWMA - RWMA Resistance Welding Manual 4th Edition