Seam Welding

Questions and Answers

There are two basic types of seam welds.

The first is a continuous seam weld.

CONTINUOUS SEAM WELD

It is a series of overlapping spot welds. They frequently would be a fluid/gas tight seal.

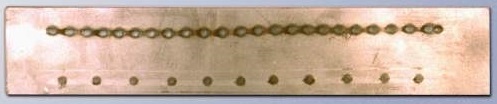

A roll-spot weld would look like this sample:

ROLL-SPOT SEAM WELD

The individual spot welds are spaced apart and they do not form a fluid/gas tight seal.

Let’s assume a barrel is being fabricated to hold a liquid. The steel is formed into the circular shape and the weld wheel is run down the length to form a continuous seam weld. Subsequently a lid and bottom are added and you have a barrel.

“The question is should the wheels be reversed and to reweld over the same surface a second time?”

Assuming that all was set up properly and the welds were spaced properly and the schedule produced good welds, the barrel should pass inspection after the first weld pass. The answer should be: “A SECOND PASS IS NOT NECESSARY”.

Secondly another pass over the same welds with the same settings will not weld. On the second pass the weld wheels are passing current through spot welds. The resistance is now very low and they will not heat up as they did when they were two sheets of metal. The area will get hot but not nugget forming hot.

There is a possible benefit to run a second pass. The initial pass may have created some stress or there may be a need for forging that some additional heat and pressure can improve with applied heat. Tempering or forging may be benefited by a second pass with some heat applied. The second pass may not melt nugget but it can temper or help forge the product that would benefit from same.

If you have to reverse for tempering or forging, there are machines sold on the market called a TWIN LAP WELDER that have a following seam wheel in a push/pull arrangement. The first wheel is making the seam/spot weld the second wheel follows and sees the same current but is over a solidified nugget and can only reheat the weld area for tempering or forging advantages. This eliminates the need to reverse. Both functions are performed in one pass.

If we are not doing a continuous weld but are doing a roll-spot, why reweld the same area if the first pass is set up properly and it ran well. There should be a good weld every “X” mm and the product is good to go to quality for inspection.

For additional information on seam welding see the available document at AWS listed below.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS Standard C1.1: 2019 Recommended Practices for Resistance Welding

The definition of resistance welding is:

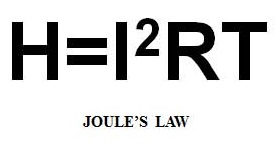

That being said the heat is generated per "JOULES LAW"

In order to make a seam weld current must flow through the desired joint area. As far as I know plastic is an electrical insulator and not able to pass current. Therefore is not a candidate for resistance welding.

To my knowledge plastic is not being resistance welded.

I am aware of ultrasonic welding of plastics. This is frictional heat formed by ultrasonic movement and pressure.

Reference: RWMA Resistance Welding Manual 4th Edition

The actual surface temperature will depend upon the weld schedule being used and the method of cooling. Is this a fluid tight seam weld or a roll spot seam weld? Is flood cooling used or not? What is the speed of the seam welding? These and other factors will have an effect upon the heat being generated and its build up. Steel no matter the thickness must reach the same temperature to weld. The thickness does dictate how much total heat is input and must be removed.

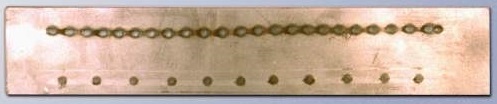

ROLL SPOT

,

CONTINUOUS SEAM - FLUID/GAS TIGHT

To address this question we will assume that we are making a liquid tight seam weld. This applies to any thickness of material. Many of the conditions listed below are common to spot welding. In seam welding the welds overlap as the weld wheels roll forward. In a seam weld the process current is developed to allow for shunting current through the trailing welds which have already been made.

INTERFACE EXPULSION SURFACE EXPULSION

Either interface or surface expulsion can lead to burn through.

There are two types of drives for seam weld wheels. One is driven by the central hub, direct drive. The other is driven by knurled wheels riding on the perimeter of the seam welding wheels, indirect drive. There are pros and cons for both systems.

Another article in this blog discusses the differences:

HOW ARE SEAM WELD WHEELS DRIVEN?

Here we will address direct driven seam weld wheels. The question is should one drive

• Both wheels

• One wheel

• or maybe none

Page 3 of 11

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.