In butt welding the steel rods must be clamped under force to be brought together. These clamps must conduct current into the rod to create the butt weld joint during the welding process. In most cases this material is Class 3 copper. This is a good conductor and has good mechanical wear and strength properties. The steel flash or bulge created during the butt weld must be removed. It can be done by hand with nippers or can be built into the machine cycle.

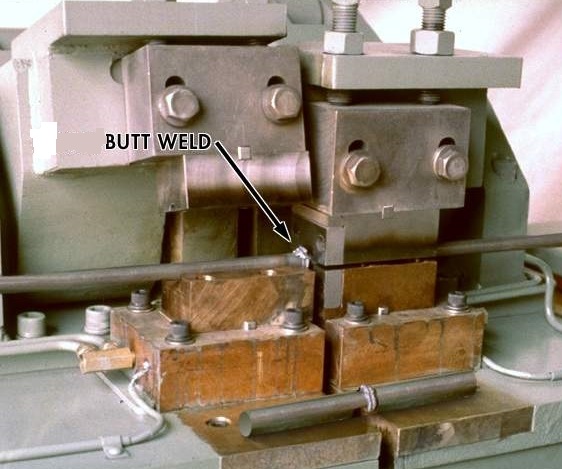

In the photo below trimming is done automatically in the butt weld sequence. The electrode on the side used for trimming the flash has a tool steel facing to do the metal cutting and Class 3 for current during the butt weld. This tool steel is frequently H13. Sometimes stainless steel has been used. After the butt weld the stationary Class 3 electrode side continues to clamp the rod and the movable tool steel faced side comes forward and trims the excess material. Then the product indexes and prepares for the next butt weld.

ROD BUTT WELDER

Butt welding rod ends together is used to make long rods or coils in a metal rod or wire mill. As each butt weld is made the resultant flash or upset material is mechanically removed for ease of drawing through the draw die. Multiple rod ends are welded end to end and then drawn through a draw die to size the rod to a slightly smaller size. It is frequently coiled on a coiler as it is drawn. When the desired numbers of rods have been welded together, the resultant coil is then drawn through a series of smaller dies until it is at the desired finish size. This is how rod is turned into a coil of wire. The welds are fast reliable and repeatable. The butt welds are virtually indiscernible.

Reference: RWMA – Resistance Welding Manual Section 5