Mechanical properties and chemical composition of the workpiece have a potential great affect upon the weld quality. Let’s examine this one at a time.

MECHANICAL PROPERTIES:

Consider a low strength steel versus a stronger alloy steel - The weld schedule will call for higher force in order to bring the stronger higher alloy parts together. Secondly a larger force will be necessary to forge and strengthen the nugget during the HOLD/cooling portion of the weld cycle.

This same scenario is true if comparing various stainless steels, aluminums, nickel alloy and others.

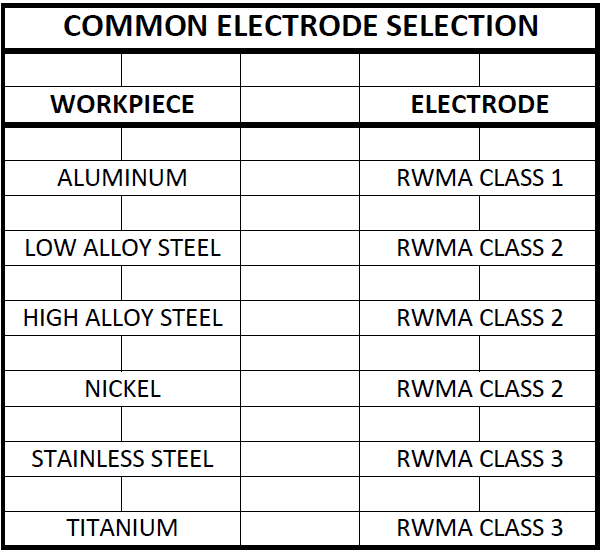

As the strength of the material increases the electrode material may also change. Lower strength materials require less force and usually are welded with RWMA Class 1 or Class 2 (Brasses, Bronzes, Aluminum, Low Carbon Steels, Lower Alloy Steels). As the material strength increases forces increase and RWMA Class 2 and Class 3 are the norm (High Strength Steels, Stainless Steels, Nickel and Titanium).

As shown many changes are necessary to insure consistent weld quality when material properties change.

CHEMICAL PROPERTIES:

One can compare low carbon steel to stainless steel. That is a chemical difference. Stainless is much stronger and more resistant and spot welds at much higher forces and lower currents than low carbon steel. It frequently is welded with RWMA Class 3 rather than the Class 2 normally used for most steels.

Aluminum of course has a much different chemistry and is highly conductive and requires very high currents for spot welding as a result. It is always welded with RWMA Class 1.

If we talk chemistries, we must talk coatings. Surface coatings introduce a multitude of chemical reactions on the part surface. This creates erratic behavior on the electrode face. Galvanized coatings is a very common example. The Aluminum oxide coating present on the surface of virtually all Aluminum is also very troublesome.

Chemical properties of the material or the surface also change the weld conditions and must be accounted for in the resistance welding process.

Reference: RWMA - Resistance Welding Manual 4th Edition