Spot Welding

Questions and Answers

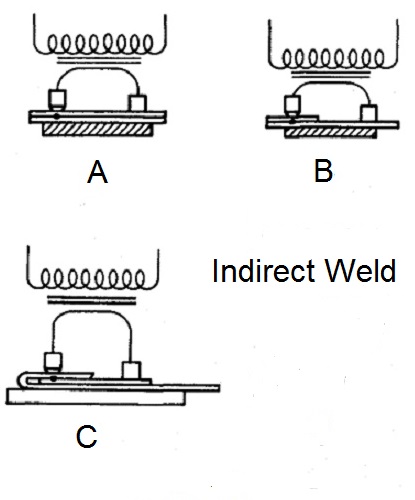

Indirect and series welds are very similar. They use similar machine and power set ups. The difference is that with indirect welding one pole off the transformer is connected to a pick-up conductor rather than an electrode. Therefore, the current returns to the transformer through this location but no weld is made. This process eliminates marking at the pickup point and the need for electrodes on the other side of the part when only when weld is required.

Note that in each sketch one electrode is contoured/pointed to concentrate the heat and weld. The other is flat to dissipate the heat and make no weld. There will be little marking of the part on the back side and none at the pickup point.

The clinched part in “C” can be welded with virtually a full cosmetic weld on the back side. Shunting currents are still present as in series welds in “A”. Current can travel in the upper sheet without passing through the weld to reach the return contact.

If the distance to the pickup electrode is sufficient this can be reduced to a minimum. In example “B” there is no shunting current since the top work-piece does not touch the pickup electrode. All current had to pass through the weld to reach the return contact point.

If all the electrodes had contoured faces, then these would be series welds at all locations. Cosmetic welds would still occur opposite the electrodes.

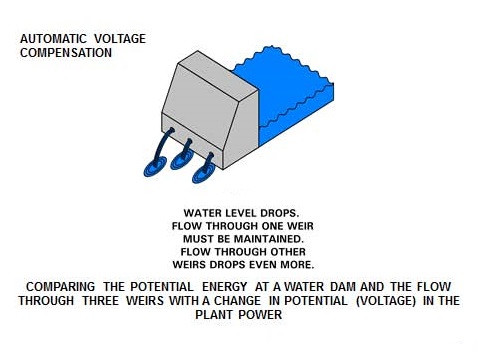

Voltage and current drops can be caused from two areas. One is the plant environment. The other is the wire mesh welder. If the plant does not have sufficient power or utility buss feed to the wire mesh welder problems can arise. As the plant turns on equipment during the day the plant voltage can drop and the input voltage to the welder can suffer. Secondary voltage and current will drop.

Along with this, pneumatic cylinders can be affected in the same manner. If sufficient air plumbing is not supplied, air pressure can drop during the day and the resistance can change if force is not maintained.

Internal changes on the welder which can affect the weld conditions are temperature, and resistances.

If the cooling water is not effectively cooling some component, it will heat up and become more resistant. If a joint connection heats up, it also may become loose and become more resistant. The conductors will be more resistant if hotter. This means less current due to higher resistance. A frayed cable or broken shunt will have a higher resistance and not conduct properly. An overheated transformer does not perform as well. Proper cooling of all components is imperative.Copper is a very conductive material and therefore can require different procedures. It can be resistance welded to similar materials. Factors that will be present are:

• Currents will be high to generate heat.

• Projections may be a good design idea to concentrate heat in a small area.

• Resistance brazing may be a method to simplify the attachment.

Sometimes increasing the current and weld time seems to hit a wall as far as nugget growth goes. It is very difficult to grow a nugget larger than the face size of the electrode.

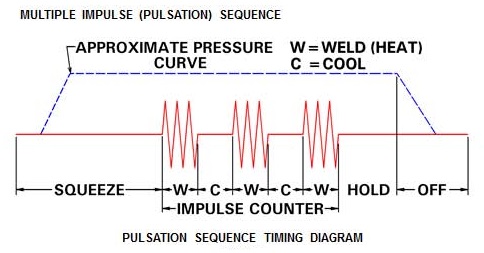

A method that some find successful to increase the face size is to use weld impulses. At the end of the weld cycle schedule an off period of one or two cycles then repeat the weld schedule. The length of the impulses may need to be adjusted to prevent overheated and expulsion.

A larger electrode face size is also an option. This will require a completely new weld schedule. The larger weld face will encourage a larger weld nugget.

Reference: RWMA – Resistance Welding Manual 4th Edition

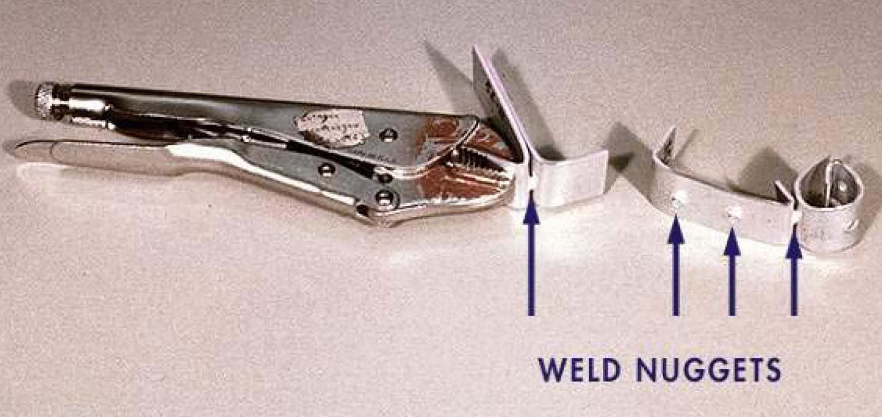

Nugget diameters are published for various materials and thicknesses in many locations.

The American Welding Society AWS C1.1 - “Recommended Practices for Resistance Welding” is one of these. Weld schedules including nugget diameters are listed for various materials. How to measure a nugget is also shown in the AWS C1.1 standard.

This blog also describes the method to measure a nugget:

HOW DO YOU MEASURE WELD NUGGETS?

WHAT IS THE FORMULA TO CALCULATE NUGGET DIAMETER IN RESISTANCE WELDING?

There is no formula to calculate a weld nugget.

Page 13 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.