The first step in developing a process is to know what is to be welded. In this case we are using stainless steel. From this we know that we have a strong, resistive material. Depending upon the material grade it could be subject to embrittlement, if it cools too quickly.

Let’s not get ahead of ourselves. Several machine set up items must be addressed before the schedule is developed. In projection welding normally several projections or even a full ring projection are being welded at the same time. For this to occur successfully the tooling and machine have to be set up properly and operating efficiently. Important factors are:

FORCE APPLICATION AND FOLLOW-UP

ALIGNMENT

PROJECTION SHAPE, SIZE & CONSISTENCY

ELECTRODE MATERIAL AND CONFIGURATION

FORCE APPLICATION AND FOLLOW-UP: The force must be applied perpendicular to the plane of the weld faying surface. A rocker arm which welds with an arc motion is not appropriate for projection welding. Straight acting press welders, table mounted weld guns with suitable force will do. The source of the force must be consistent and fast. The servo or cylinder must move smoothly with no hesitation. Fast follow up refers to the ability to maintain full force as the projection begins to collapse. If the machine does not maintain/follow up with full force at the moment the nugget begins to collapse and could be solidifying the weld strength will be compromised. Low inertia cylinders, machines and servos are manufactured for this purpose. Low inertia holders are also available to retro fit slower machines. This is a case for periodic preventive maintenance to insure that a cylinder, servo is alwasy in good working order and not starting to hang up.

LOW INERTIA WELDER FAST FOLLOW-UP HOLDER

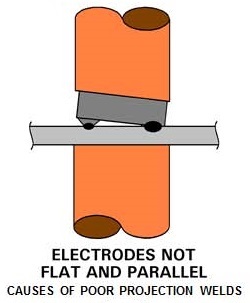

ALIGNMENT: The tooling and part must be held and force applied with good alignment. All projections must be in contact at the same time under the same force or they will not heat evenly. One or more will carry the bulk of the current and upset before another if misaligned. When the final one makes contact it likely will arc and expel as weld flash. Tooling must be maintained in good repair to maintain alignment.

PROJECTION SIZE, SHAPE & CONSISTENCY: Projections come in many sizes and shapes including full rings. The only requirement is that on all parts they be consistent. If you are set up to weld four projections and one is missing then the power meant for four will be driven through three. They will heat very fast. Likely expulsion will occur and the resultant welds may or may not be acceptable. In either case one is missing. If a projection is oversized or undersized a similar scenario will occur. It will make contact before or after the others if it sits higher than the others and get most of the current. It will get very hot expel and or collapse early. The others will then come in contact. If it is short in height the opposite will occur. The process will be out of sequence and the weld results will be compromised.

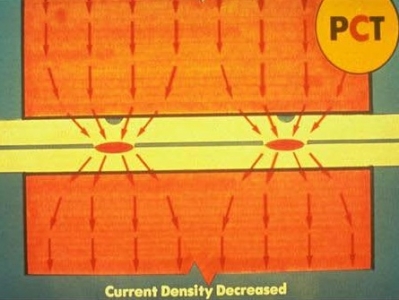

ELECTRODE MATERIAL AND CONFIGURATION: Generally projection welding electrodes are large flat surfaces. Sometimes holes are incorporated for locators (nut welding). In crosswire welding the lower electrode may be a single long bar of copper alloy or refractory material spanning many welds. The electrode delivers force and amperage through a relatively large surface area into the part being welded. Secondarily they provide cooling of the part. The part by design concentrates the current and force to create heat and forging at a concentrated location. Projection welding electrode life is long when compared to spot welding electrodes. The wear is frequently mechanical abrasion. RWMA Class 2 is the first choice for electrode material in projection welding. If mechanical wear and tear is a little heavy and Class 2 has to be faced too often try RWMA Class 3. It is mechanically harder and more resistive to wear than Class 2. If there is a lot of heat and excessive wear, RWMA Class 11 refractory metal electrodes may be the best choice.

PROJECTION WELDING CONCENTRATED CURRENT AND FORCE

FROM LARGE FLAT FACED ELECTRODES

WELD SCHEDULE: After addressing the machine and part variables and making the set up adjustments, it is time to address the weld schedule. With a proposed weld schedule one would prepare to make the first sample welds on coupons to sample parts.

Basic weld schedules are available in AWS Standard C1.1for various materials including stainless steel. This information can be used as a starting point. If a projection weld schedule is not available and a spot weld schedule for the same material is available use it as a guide. Multiply the current by the number of projections if they are far apart, if close together adjust to a lower multiplier. Force is determined in the same manner. Time will be the same as a spot weld.

SEE ARTICLE THIS BLOG: HOW DO YOU DEVELOP A PROJECTION WELD SCHEDULE?

Remember to always start at power levels well below where you expect to end up. Run a test. Evaluate the sample. Adjust the settings. Rerun the test. Evaluate again. In the case of some high alloy steels a slow cool or tempering cycle may need to be incorporated into the weld schedule to reduce the brittleness of the weld. Continue this process until a good weld is produced. Then record all values.

MAINTENANCE: During operation Machine Maintenance will be required to keep the process under control per AWS J1.2 Guide to the Installation and Maintenance of a Resistance Welding Machines

Reference: AWS C1.1 Recommended Practices for Resistance Welding

AWS J1.3 Specification for Materials Used In Resistance Welding Electrodes and Tooling

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Photos courtesy of: T.J. Snow Co. and Tuffaloy Products Inc.