Projection Welding

Questions and Answers

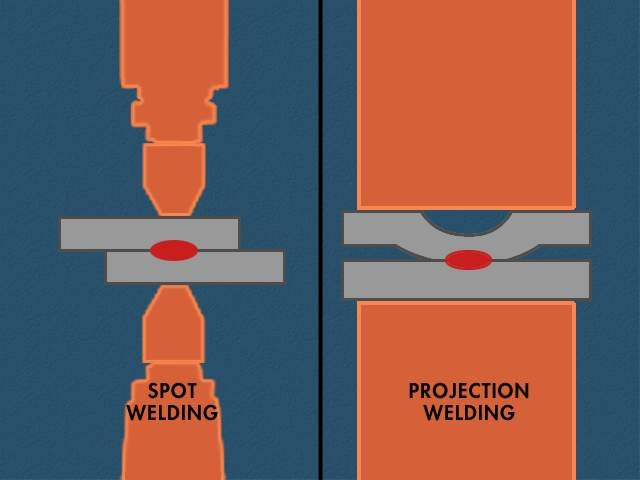

By the nature of the process, projection welding electrodes deliver the pressure and current through a large flat surface area as compare to spot welding.

This results in greatly reduced surface wear on the face of the projection welding electrodes. Their life is generally much longer and require minimal maintenance. The wear on the face of the projection welding electrode may have little if any affect upon the weld quality. It may only affect the cosmetic appearance on the part surface it contacts. In many cases this is not an issue.

As stated projection welding electrodes can run a long time without dressing.

If projection electrode wear does impact weld quality it is time to dress. If the part begins to stick to the electrode because of cracks or roughness, it is time to dress. Watch your weld quality but expect some other problem to crop up and influence your need to dress the projection weld electrode.

When dressing is desired for whatever reason be it part surface, sticking or convenience a light resurfacing will usually suffice. This can be on the machine or removed and done in a machine shop.

See another article in this blog:

CAN PROJECTION WELDING ELECTRODES BE DRESSED EASILY?

There is no canned number or welds at which this will occur. It should be more than spot welding. After a few production cycles you will learn what your normal process issues are and know what to expect and when. A routine will be easy set up and maintain for your process.

References: RWMA – Resistance Welding Manual 4th Edition

Resistance spot welding of copper is possible but requires great care due to its high conductivity. Projection welding eliminates some of the issues by concentrating the current in a small area which concentrates the heating. This may help. The electrode can spread the current input over a large surface area not just the weld area. This makes it an easier job for the electrode. In this application of a copper cylinder beingprojecton welded to a copper plate a grove to match the cylinder can be cut in the upper electrode. Current can flow into the part the full length. The cylinder is only going to mate with a cross projection in a small portion of that length where heat will be briefly generated between the cylinder and the plate at the projection/point contact.

The electrode on the plate side should also be a large flat surface electrode to serve the same function. The heat by design will concentrate at the projection in the plate.

For a spot welding the electrode material should be RWMA Class 13 or 14. For this projection welding application RWMA Class 2 is probably sufficient. If mechanical wear is too much try RWMA Class 3. Both Class 2 and 3 are are more available and economical than Class 13 and 14.

The real issue in this process may be that the cylinder and projection are likely going to collapse. Is that an issue??

An alternate process is a resistance braze. The joint is made with the addition a small amount of braze material in the joint area. Resistance heating is used to heat the joint area up to melt the braze alloy and resolidify at a force that would not collapse the cylinder.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS C1.1 Recommended Practices for Resistance Welding

CMW Resistance Welding Products Catalog “Electrode Materials For Spot Welding”

As stated in several articles millions of weld nuts and bolts are welded every month probably each week. The industries include automobiles, aircraft, appliances, office furniture, appliances and many others. Their function can be very critical dependent upon the application. Assorted projection welding nuts are shown below.

ASSORTED WELD NUTS

The quality of these projection welds is very important. They are tested for torque, push off and set down.

In this blog there are three articles that discuss the status of testing:

WHAT ARE THE QUALITY STANDARDS FOR NUT PROJECTION WELDING?

WHAT VARIATION IS EXPECTED IN THE PUSH-OFF TEST OF A PROJECTION WELDED NUT?

IS THERE A WELD STANDARD FOR WELD NUT SET DOWN?

The conclusion of these articles is that at this time there are no published strength or test standards available for projection nut or bolt evaluation.

The articles do offer guidelines to develop values that can be used in many applications.

References: AWS Welding Journal: January & March 2011 Q & A “Quality of Forged Projection Weld Nuts” by DONALD F. MAATZ JR.

AWS C1.1 Recommended Practices for Resistance Welding

Attaching weld nuts is a projection weld due to the design of the weld nut. An attempt to direct power from a single transformer to three weld nuts at once and maintain a balanced current to all three would be difficult.

If one wanted to use one transformer to make multiple welds a cascade arrangement would be a better set up. Here the transformer is attached to all three weld guns. The weld control is a cascade arrangement that allows only one gun at a time to close and have current flow.

FOUR CASCADE CONTROL

In the above control four cascade welds can be programed independently. Each weld would made independently in sequence. This reduces demand on the buss and the transformer since this is four individual welds not four at one time.

Reference: RWMA Resistance Welding Manual 4th Edition

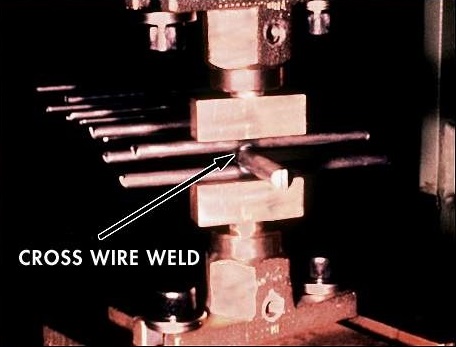

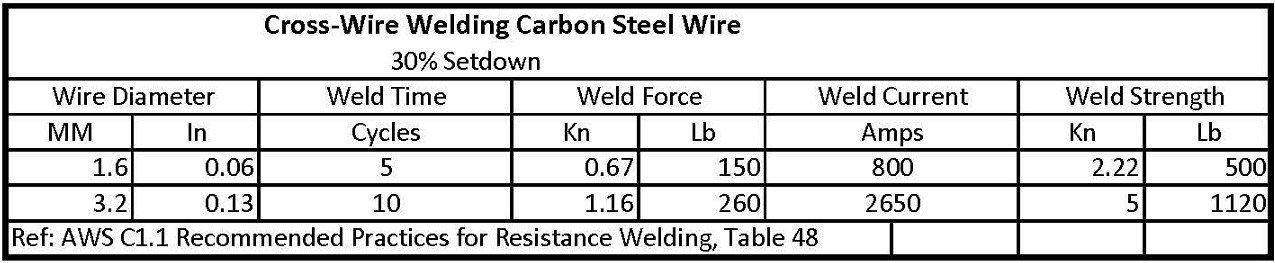

Cross wire welding is a form of projection welding. When two wires are crossed that is a point contact. The heat and force are concentrated at that point contact. Even welding a wire to a sheet is a projection weld concentrated in a line point contact. Weld schedules are available in the literature for this type of operation.

There is an article in this blog on this subject which answers this question:

WHAT SCHEDULE SHOULD BE USED TO CROSS WIRE WELD 9 GAGE LOW CARBON GALVANIZED STEEL WIRE?

This article offers an example of the data that is available in AWS Specification C1.1 for weld schedule set up. Force, current and time are shown as starting points. The data will not cover all circumstances but does offer enough information that one can develop a starting point for most circumstances including bare versus coated materials.

Electrode alloy selection is generally RWMA Class 2 or 3. The choice depends upon wear. Normally a flat face is used but a grove to match the wire is sometimes incorporated. The flat face will eventually have a groove wear in. The electrode face size is usually large so the current flows into a large surface area of the part. One is not trying to create heat at this interface.

Every machine and set up is different and the actual set up schedule will vary from the book values. Use the values tabulated as a guide. Start at low power values to avoid dangerous expulsion. Gradually increase the time or power with caution until the desire weld is accomplished. Expect coated materials to require a higher current level than bare material and they may exhibit more expulsion.

Reference: AWS: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA: Resistance Welding Manual 4th Edition

Page 2 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.